In the global electric drive of new energy vehicles, permanent magnet motors account for nearly 90%. Among them, permanent magnets added with heavy rare earths such as dysprosium and terbium have high magnetic energy product and high coercive force, and the corresponding rare earth permanent magnet motors are highly respected for their small size, light weight, high efficiency, and good characteristics. . However, due to the small reserves of heavy rare earths in rare earth mines, with the popularization of new energy electric vehicles and large-scale production of rare earth permanent magnet motors at home and abroad, the use of heavy rare earths will face resource shortage bottlenecks. At present, some developed countries have used low-weight rare earth permanent magnets in motor products.

As a class of metal elements with special physical and chemical properties, it has been widely used in many high-tech fields. There is a vivid metaphor in the market. If oil is the blood of industry, then rare earths are the vitamins of industry, especially for the automobile industry. In permanent magnet motors, neodymium iron boron (NdFeB) is one of the most commonly used permanent magnet materials, with high remanence and energy product. And its three rare earth constituent elements: neodymium (Nd), praseodymium (Pr), and dysprosium (Dy), are of great help in improving the dynamic magnetism, heat resistance, prolonging life and reducing noise of the motor. Therefore, despite the high cost, permanent magnet motors have always been the mainstream configuration of new energy vehicles.

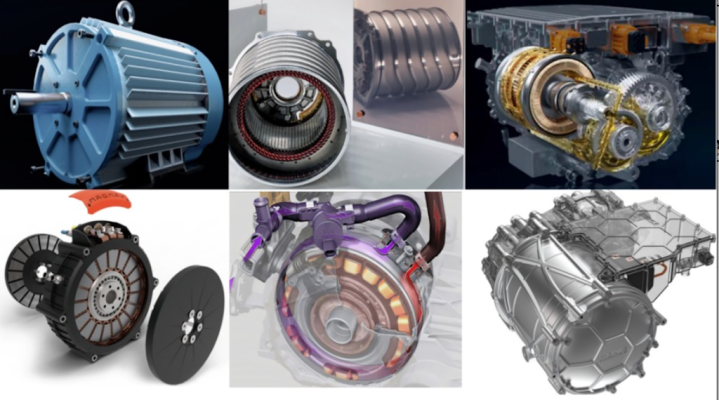

Dayang Motor recently stated in an institutional survey that rare earth permanent magnet synchronous motors are currently the mainstream technology route for driving motors in new energy vehicles, with a conversion efficiency of over 90%. At present, the future technology route may develop in the direction of reducing the use of rare earths. Specifically, it is to use less heavy rare earths and more light rare earths.

Generally speaking, the rare earths used in motors refer to heavy rare earths, such as terbium (Tb), dysprosium (Dy), holmium (Ho), neodymium (Nd), praseodymium (Pr) and other elements. Different motors use different heavy rare earth elements because of their small stock and high cost. Now, companies are turning to use more light rare earths and reduce the use of heavy rare earths. Industry insiders said in an interview with reporters that the reserves and prices of heavy rare earths and light rare earths vary greatly. Lower, only tens of thousands of yuan / tons. Therefore, the industry has achieved good results in promoting the elimination of heavy rare earths and reducing the amount of light rare earths, praseodymium and neodymium.

Industry insiders also made a detailed analysis on this: first, the global rare earth reserves are sufficient, so there is no need to worry at all; second, under the current technological development conditions, the use of rare earths in motors is much less than before, and the degree of dependence on rare earths has increased. Second, it is worth mentioning that with the development of the motor recycling industry, the rare earth materials of waste motors can be technically purified and recycled close to 100%, which is also an important source of rare earths. "The rare earth materials needed to manufacture one motor in the past may be used to produce two new motors in the future." He said that as the new energy vehicle market continues to grow in the future, motor recycling may be an important source of rare earth materials, "Rare earth "Dafeng" is also expected to be realized ahead of schedule. At that time, rare earth materials may achieve an organic dynamic balance just like new energy vehicles.

As a resource-rich country, China has chosen to use new energy as a breakthrough to promote industrial transformation in the choice between continuing to maintain high-energy-consuming operations or "scraping the bones to heal the wounds" of the original industrial system.

We can also see that China has continued to make major moves in the field of new energy in recent years, promoting its development through policy support, market introduction, and enterprise support. In 2022, the national key research and development plan "Special Report on New Energy Vehicles" proposes to study high-efficiency rare-earth-free drive motors and accelerate the development of ultra-efficient rare-earth-free motors. This means that the rare-earth-free motor has entered the national important technical strategic reserve, has become a "new blue ocean" in industrial product equipment, and has become a new driving force on the road to resource transformation.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語