Introduction

Hot-pressed neodymium magnets are also known as hot-deformed Nd-Fe-B magnets. Hot-pressed and hot-deformed Nd-Fe-B magnets are typically produced from rapidly quenched powder following crystallization treatment. Hot-pressed magnets are characterized by their radially oriented, anisotropic Nd-Fe-B ring magnets, which are achieved through the mechanical pressing of Rare Earth powders during a process known as Backward Extrusion. The ring magnets manufactured by the hot-pressed process exhibit radially oriented, anisotropic properties. As early as 2010, Daido Electronics of Japan commercialized a high-efficiency ring magnet and introduced it as the NEOQUENCH-DR series. Hot-pressed neodymium magnets find extensive applications in various fields, including EPS (Electric Power Steering) motors, servomotors, and more. These motor ring magnets surpass the performance of sintered magnetic rings, and Tommy will explore their benefits from multiple perspectives below.

How are hot-pressed neodymium magnets better than sintered NdFeB magnetic rings?

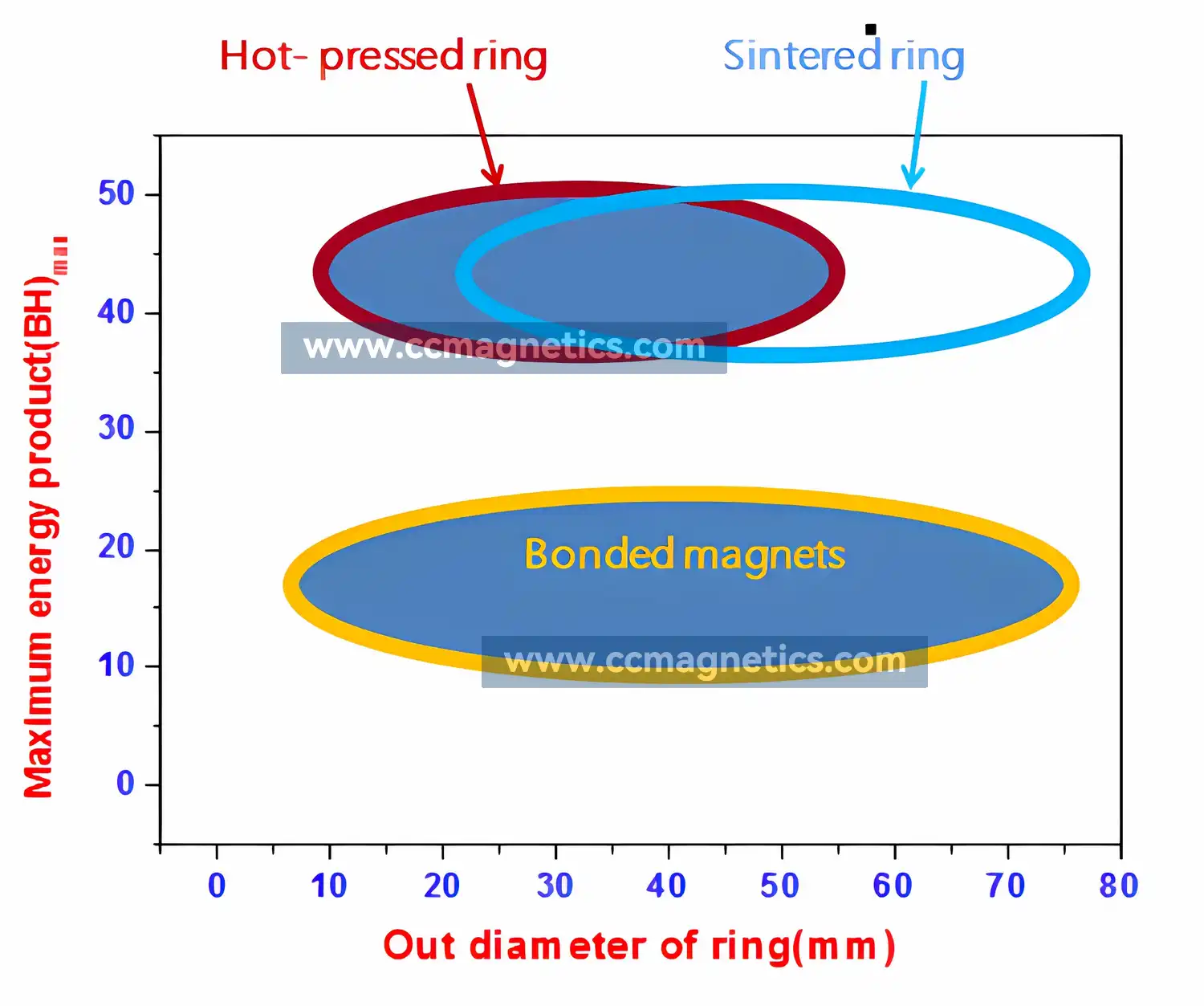

1. Hot-pressed magnetic rings can be made with a smaller inner diameter, whereas the magnetic field of sintered Neodymium weakens rapidly as the inner diameter decreases. As a result, the magnetic properties of sintered neodymium magnets decrease significantly. However, the performance of hot-pressed NdFeB ring magnets doesn't weaken with decreasing diameter. Sintered NdFeB cannot achieve rings with extremely small diameters. For example, when you need a ring magnet with a diameter of less than 15mm.

2. Hot-pressing allows for thinner production, without affecting the surface magnetism due to changes in the magnetic ring's wall thickness. The wall thickness of sintered NdFeB is usually thicker, ranging from 2-4mm, whereas the common wall thickness of hot-pressed magnets is 2-3mm. Due to the technological advantage, The magnetization saturation of sintered magnetic rings will be affected by wall thickness, but hot pressing will not, the magnetic saturation of hot-pressed rings is better than sintered NdFeB magnets.

3. Without considering the coating of the magnetic iron, hot-pressed magnetic rings have better corrosion resistance due to their technological advantage.

4. Hot-pressed magnets exhibit higher toughness and flexural strength than sintered magnets, making them more robust than sintered NdFeB magnets.

5. Hot-pressed magnets offer better cost-performance ratios, shorter lead times, and higher temperature resistance compared to sintered NdFeB ring magnets with equivalent performance.

| Item | Sintered ring | Hot-pressed ring |

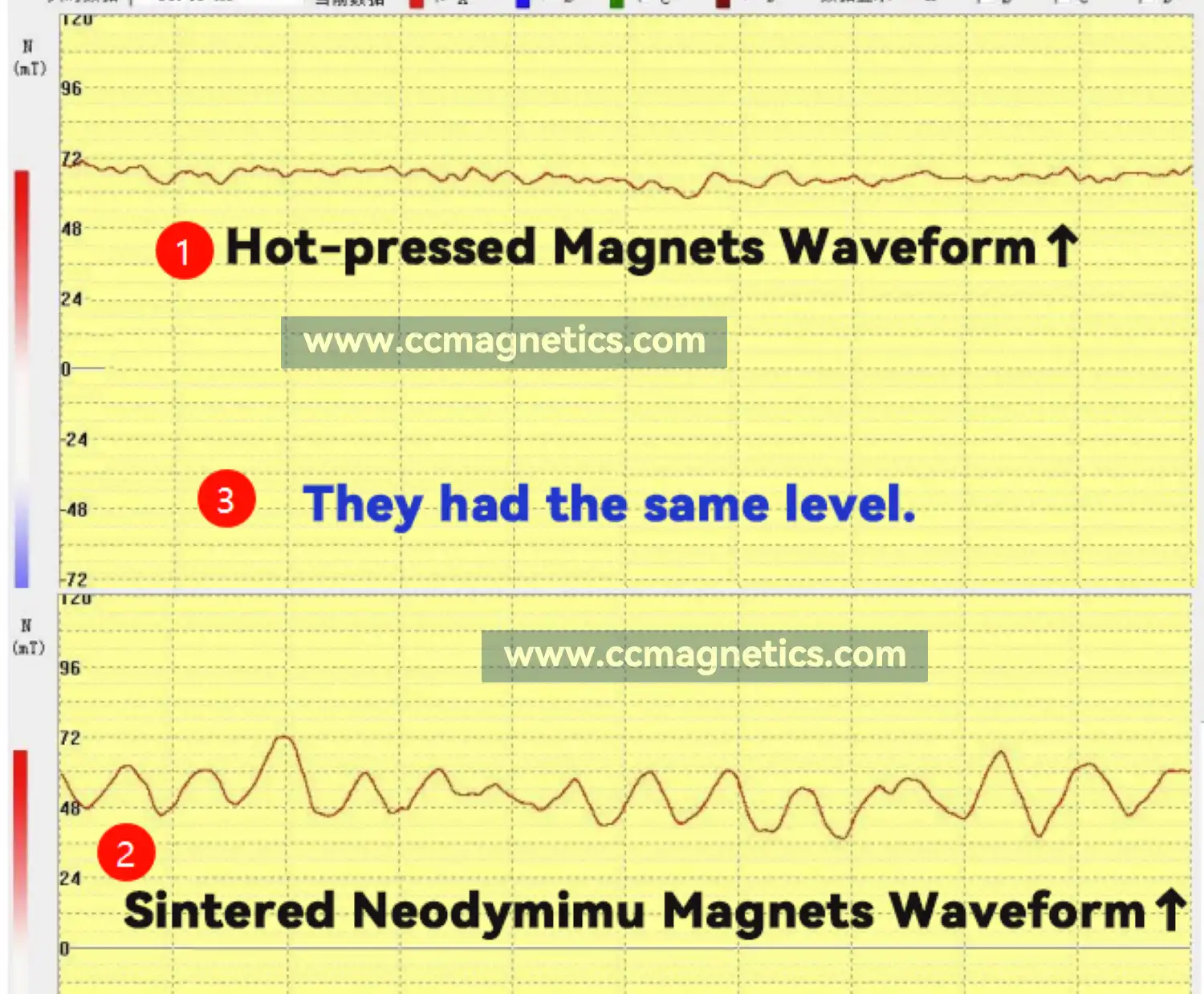

| Surface magnetic flux waveform | Rectangular wave | Rectangular wave |

| Number of poles | Variable by magnetization | Variable by magnetization |

| Magnetized position | Variable by magnetization | Variable by magnetization |

| Skew magnetization | Yes | Yes |

| Recommended inside-to outside diameter ratio | ~0.8 | ~0.8 |

| Recommended length (mm) | 1~50 | 1~50 |

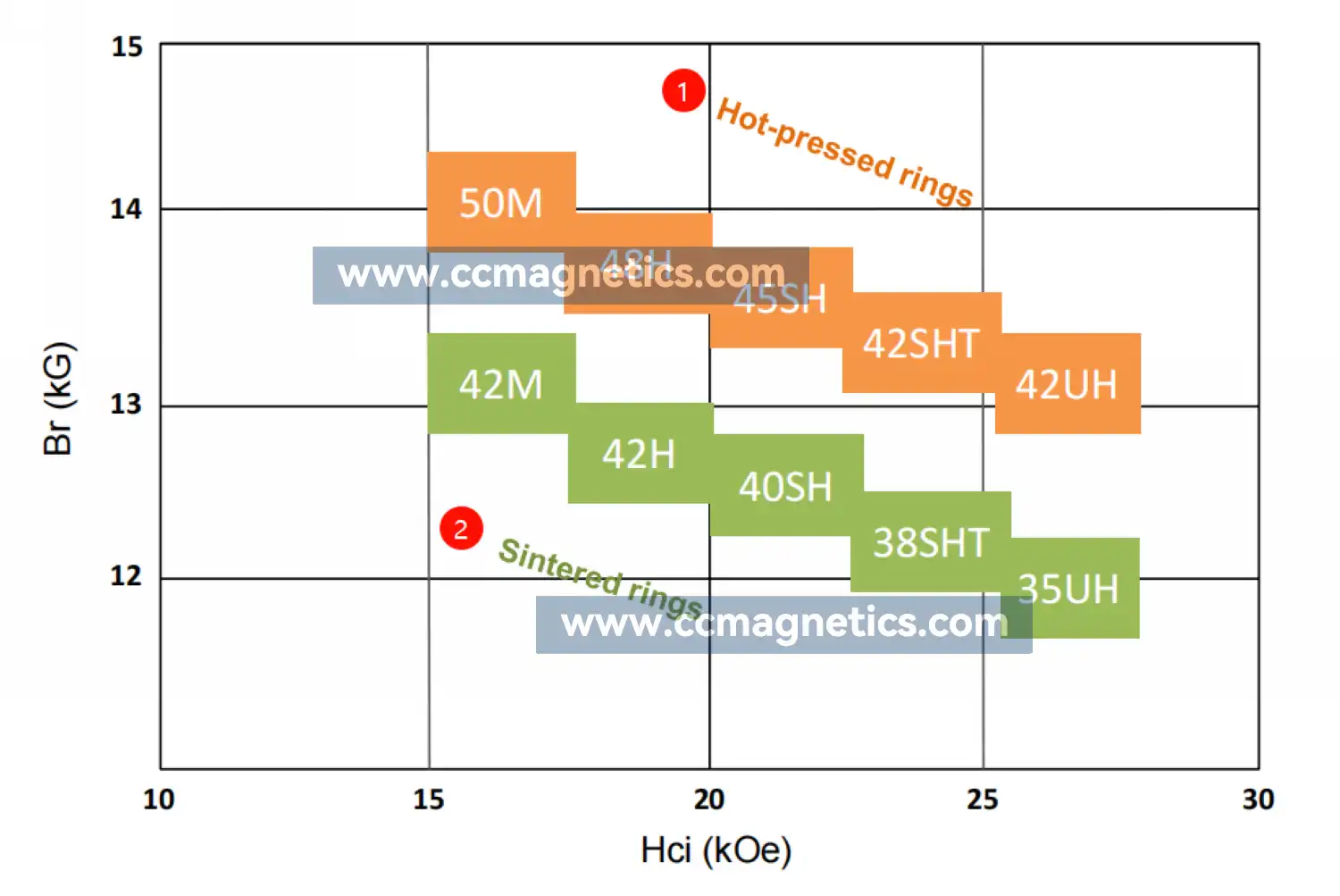

| Grades | N45,45H,42SH,35UH | N48,48H,45SH,38UH |

| Recommended OD (mm) | D20~D70 | D8~D50 |

| Corrosion resistance | poor | good |

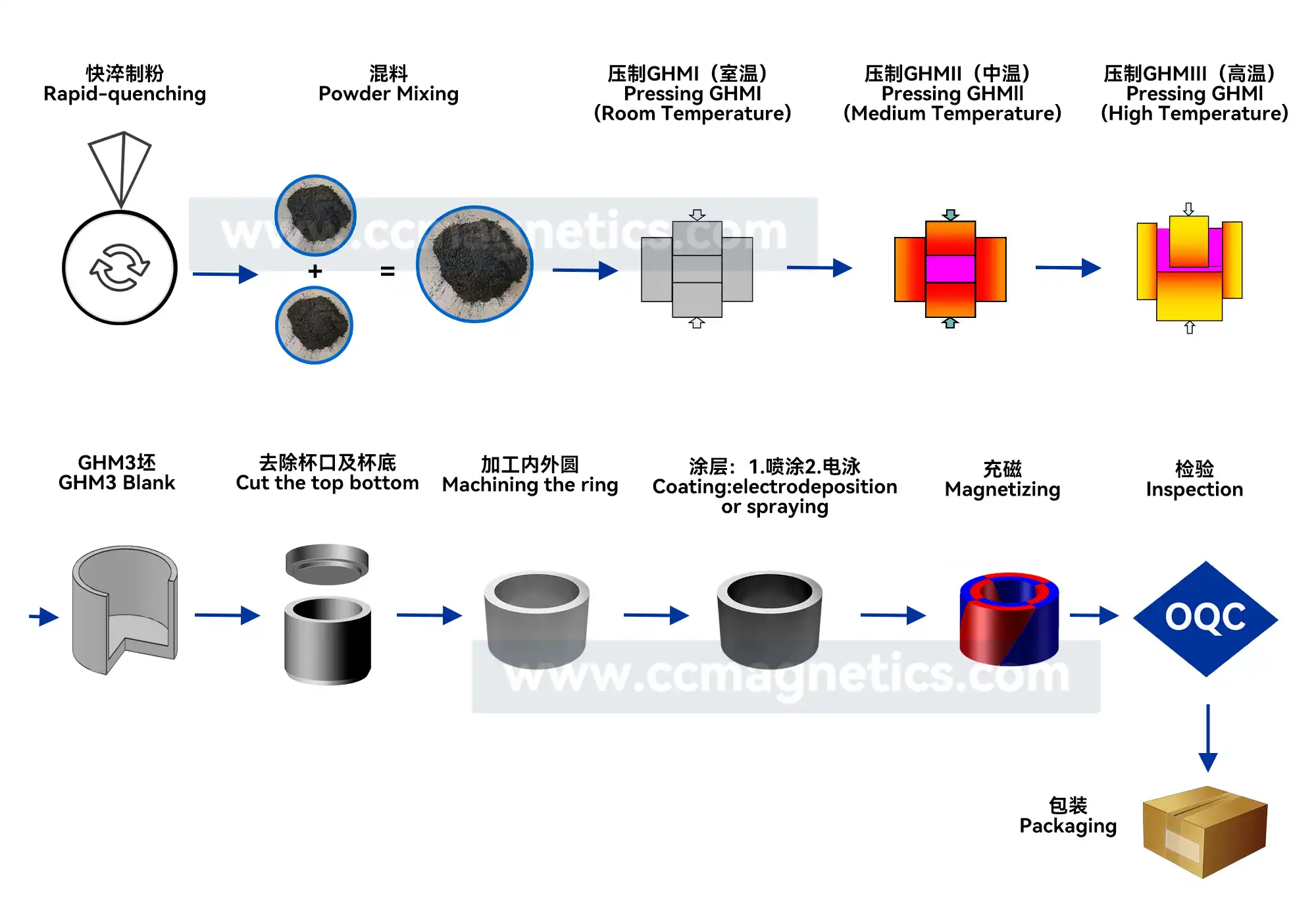

Hot-pressed neodymium magnets manufacturing process

Hot-pressed neodymium magnets dimensions and tolerances

| Dimensions (mm) | min | max |

| Inner diameter/Outer diameter | 0.7 | 0.9 |

| Height | 0.5 | 50 |

| Diameter | 10 | 50 |

| Optimum Diameter | 20 | 40 |

| Tolerances(mm) | OD | ID | H | concentricity | roundness |

| Machined magnets | ±0.03 | ±0.03 | ±0.1 | 0.03 | 0.03 |

| Coated magnets | ±0.04 | ±0.04 | ±0.05 | 0.05 | 0.03 |

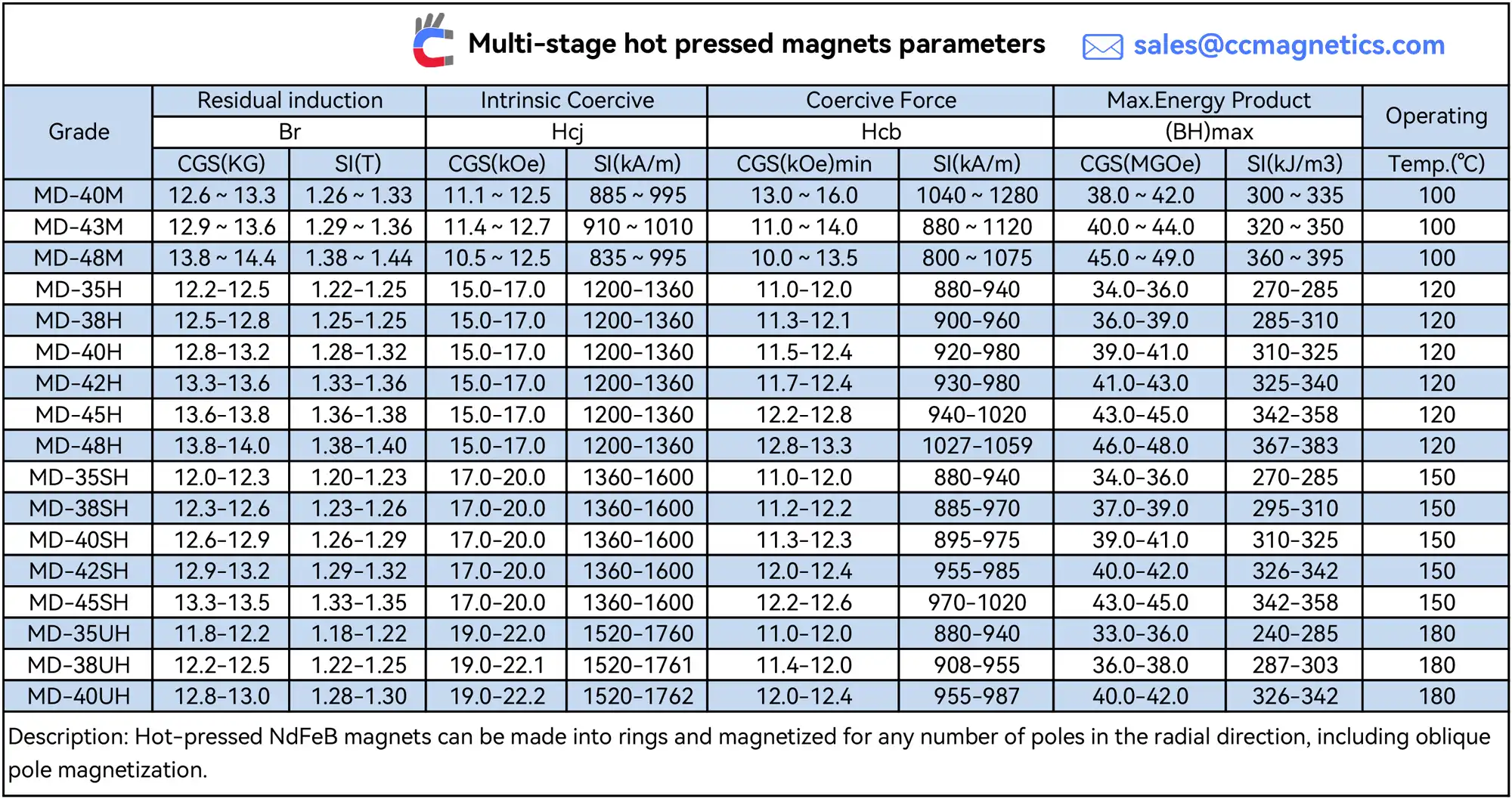

Hot-pressed NdFeB ring magnet properties

Magnetic angle deviation of hot-pressed neodymium magnets

| Size | Pressing Method | 1 | 2 | 3 | 4 | average |

| D39.35*D32.5*27 | Hot-pressed | 0.52° | 0.38° | 0.45° | ||

| D39*D30*25.5 | Rotation sintered | 14.55° | 13.92° | 12.55° | 14.66° | 13.92° |

| D14*D10*20 | Rotation sintered | 22.44° | 24.68° | 22.89° | 22.96° | 23.24° |

| D30*D24*20 | Rotation sintered | 18.39° | 18.41° | 15.87° | 14.36° | 16.75° |

Rotation pressed ring have magnetic angle deviation 10°~20°

Hot-pressed neodymium magnets have magnetic angle smaller than 1°

Hot-pressed neodymium magnets applications

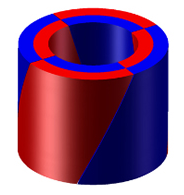

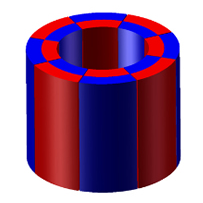

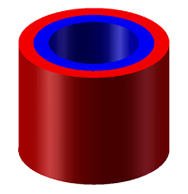

| Magnetization pattern |

|

|

|

|---|---|---|---|

| Application examples |

|

|

|

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語