Posted: January 21, 2025

Please refer to the principle animation diagram: The Max RPM is determined by the point that the centrifugal forces related to the inertia of the coupling generates enough stress to cause the part to yield. In simple terms, these are the speeds where the coupling would theoretically rip itself apart from the centrifugal forces.

Posted: October 27, 2024

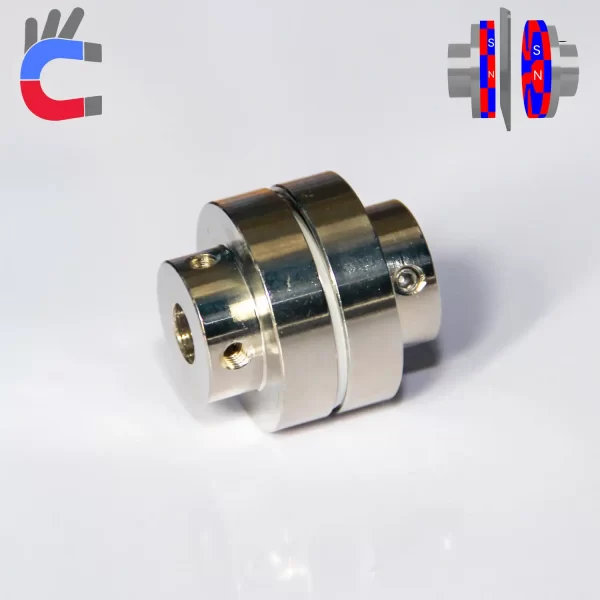

Sure, you just need to tell us your shaft diameter. There are two customization options for the XC series: Option A: Standard: Customizable shaft holes; Optional: Stainless steel 304 ( UNS S30400 )or stainless steel 316L(UNS S31603, Can be used in sea water) surface materials; NdFeB(Working temperature;) or Samarium Cobalt internal magnets(Working temperature;) Option B: [...]

Posted: October 27, 2024

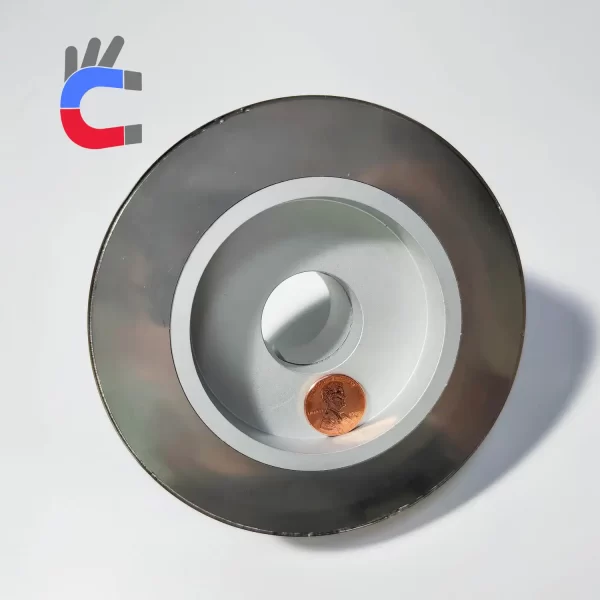

PN: XD-50 Part Number (A) O.D (B) I.D (C) Height D E F G H M Torque (interval: 1mm) Torque (interval: 5mm) XD50-B 50 12,15,20 22 34 13 6 20 5.5 M5 4.2N.m 1.5N.m XD-50 means the outer diameter is 50 mm (1.97 inches), and the inner shaft we recommend is 12,15,20mm ( 0.47,0.59,0.79 inches.) [...]

Posted: October 27, 2024

Normally we need 30 days to produce them. Since we are the original factory, we also provide OEM services for many brands. If there are not many orders in our production queue, this time will be advanced by 1 week.

Posted: October 27, 2024

Since different customers have different requirements for shaft diameter of magnetic couplers. Therefore, we only have magnets in stock, and the magnetic coupler housings are only produced after receiving orders.

Posted: October 27, 2024

Absolutely. We offer discounts for bulk orders. The larger the quantity, the greater the discount. We are keen to establish long-term and stable cooperative relationships with our customers.

Posted: October 27, 2024

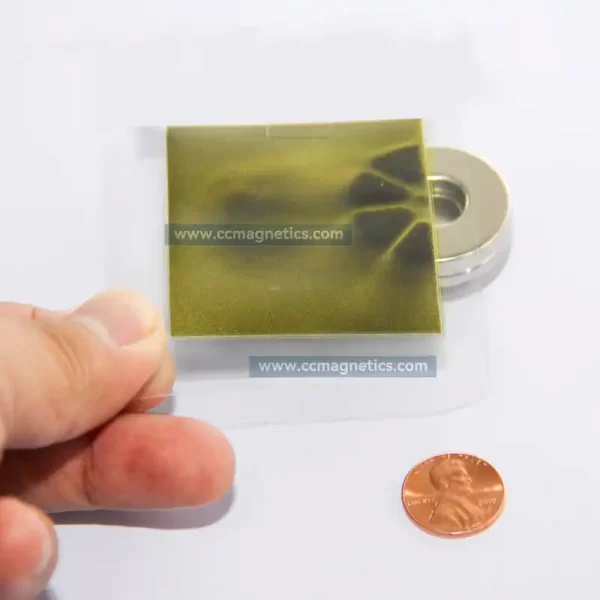

Yes, it's necessary. The strongest magnetic part of the magnetic disc coupler is primarily located in the red area shown in the figure below. Before implementing any shielding measures, it's crucial to test the surface magnetism to make an informed decision. We typically provide customers with a Magnetic Field Viewing Film. This tool helps identify [...]

Posted: October 27, 2024

We can only sell magnets. If you require magnetic couplings, we suggest purchasing them. Welding NdFeB magnets to the inside of a stainless steel metal shell requires significant welding experience and specialized equipment to secure the magnets during the process. Lacking this expertise could lead to potential injuries for the welder due to the strong [...]

Posted: October 27, 2024

It can be disassembled, and a cutter is needed to cut it from the red line. But you need to make sure you have the equipment to weld the stainless steel so that you can assemble them again.

Posted: October 27, 2024

The operating temperature range of the standard magnetic disc coupling (XD-Series) is -20°C to 80°C. Our magnets are fixed inside the metal housing using 3M adhesive, which is a high temperature resistant, environmentally friendly and safe material. The housing of the disc coupling will be made of 304 stainless steel with welded seams.The stainless steel [...]

Posted: October 23, 2024

Standard XD-series magnetic disc couplings configuration materials: Stainless steel 304 (UNS S30400) and neodymium permanent magnets. Configuration materials: Stainless steel 304 (UNS S30400) and neodymium permanent magnets. Disc coupling type Surface material Magnet coating Magnet type Shaft fixing method Operating Temp Features Default configuration SAE 304 stainless steel Ni-Cu-Ni NdFeB Type-A 80C(176F) Most cost-effective, applicable to [...]

Posted: September 27, 2024

Polyvinyl chloride (PVC) is the world's third-most produced synthetic plastic polymer (after polyethylene and polypropylene). PVC was once the world's largest-volume plastic and has a wide range of applications. PVC exists in both rigid (sometimes abbreviated as RPVC) and flexible forms. Rigid PVC is used in construction for pipes and windows. It is also used [...]

Posted: June 4, 2024

Disc Type Magnetic Couplings: Shaft Fixing Methods Disc type magnetic couplings offer various shaft fixing methods to suit your application's needs. Here's a breakdown of the three main options: Type A: Suitable for magnetic disc couplings with diameters up to 24mm. This method is not recommended for larger diameters due to potential slippage. Type B [...]

Posted: May 10, 2024

Decreased maximum 0.1% per year.

Posted: May 1, 2024

Currently, the maximum torque of the co-axail type couplings coupler provided by CCmagnetics is 84Nm, and the maximum torque of the disc-type coupler is 18.5Nm. The torque of the Disc-type coupler is related to the installation gap. RELATED PRODUCTS

Posted: May 1, 2024

Periodic inspection the performance of the magnetic source, ensuring cleanliness, and avoiding exposure to external magnetic fields are key to maintaining the performance of magnetic couplings. Perform regular maintenance according to manufacturer's recommendations. RELATED PRODUCTS

Posted: May 1, 2024

Applications currently benefiting include: pumps, fans, blowers, centrifuges, and bulk handling equipment. Industries served include: water and wastewater treatment, pulp and paper manufacturing, power generation, oil & gas processing, cement, mining, chemical & food processing, irrigation, maritime and HVAC systems. These installations are demonstrating significant energy savings and reduced system vibration. RELATED PRODUCTS

Posted: May 1, 2024

Selecting a suitable magnetic coupling requires consideration of application needs such as torque requirements, working environment, installation space and quality standards. Working with a manufacturer to tailor a solution to your specific needs is the best option. CCmagnetics is the original manufacturer and we can provide you with free solution design. RELATED PRODUCTS

Posted: May 1, 2024

If your magnetic coupling is unable to transmit torque, it may be due to demagnetization or damage to the magnetic source. Check the performance of the magnetic sources to make sure they are not disturbed by external magnetic fields. RELATED PRODUCTS