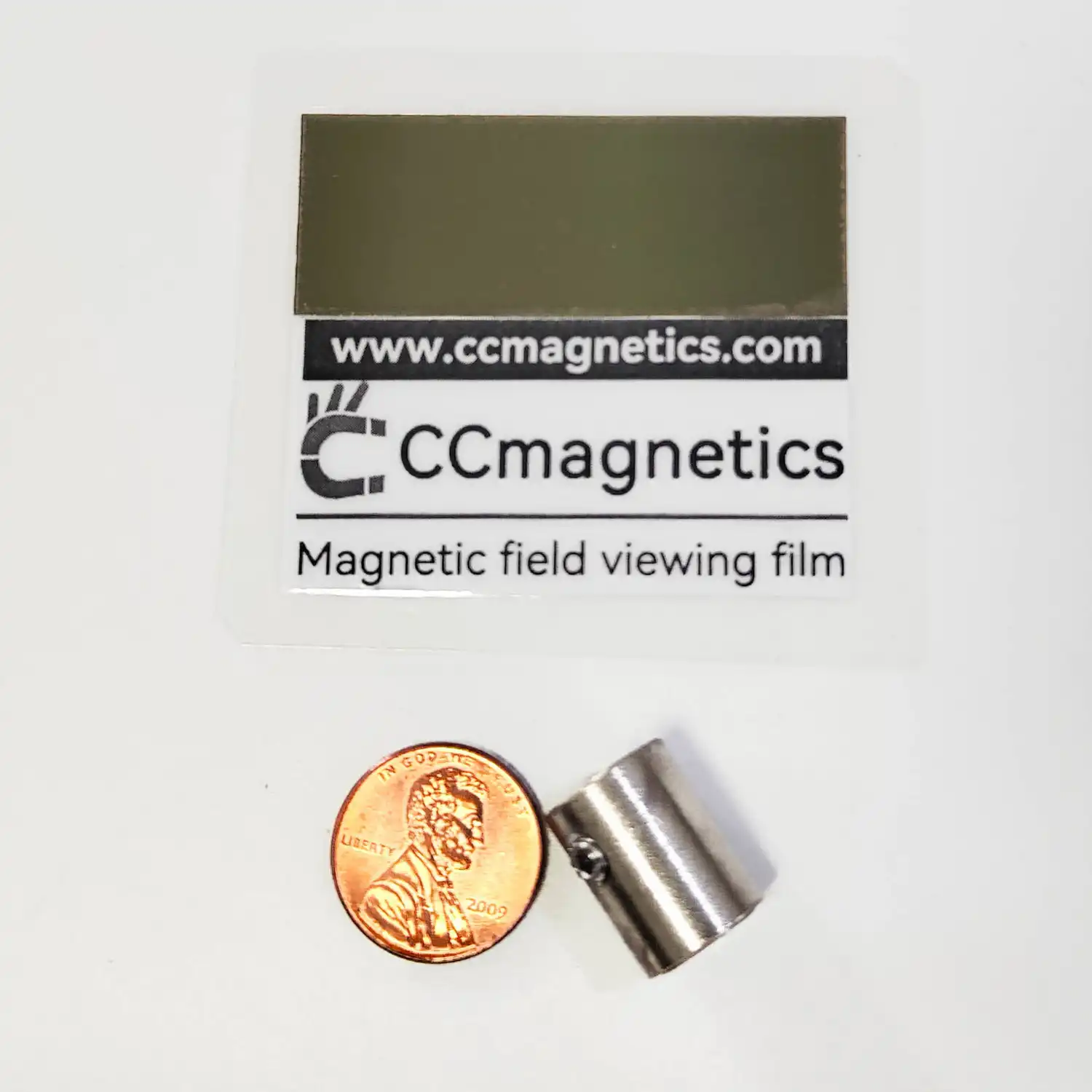

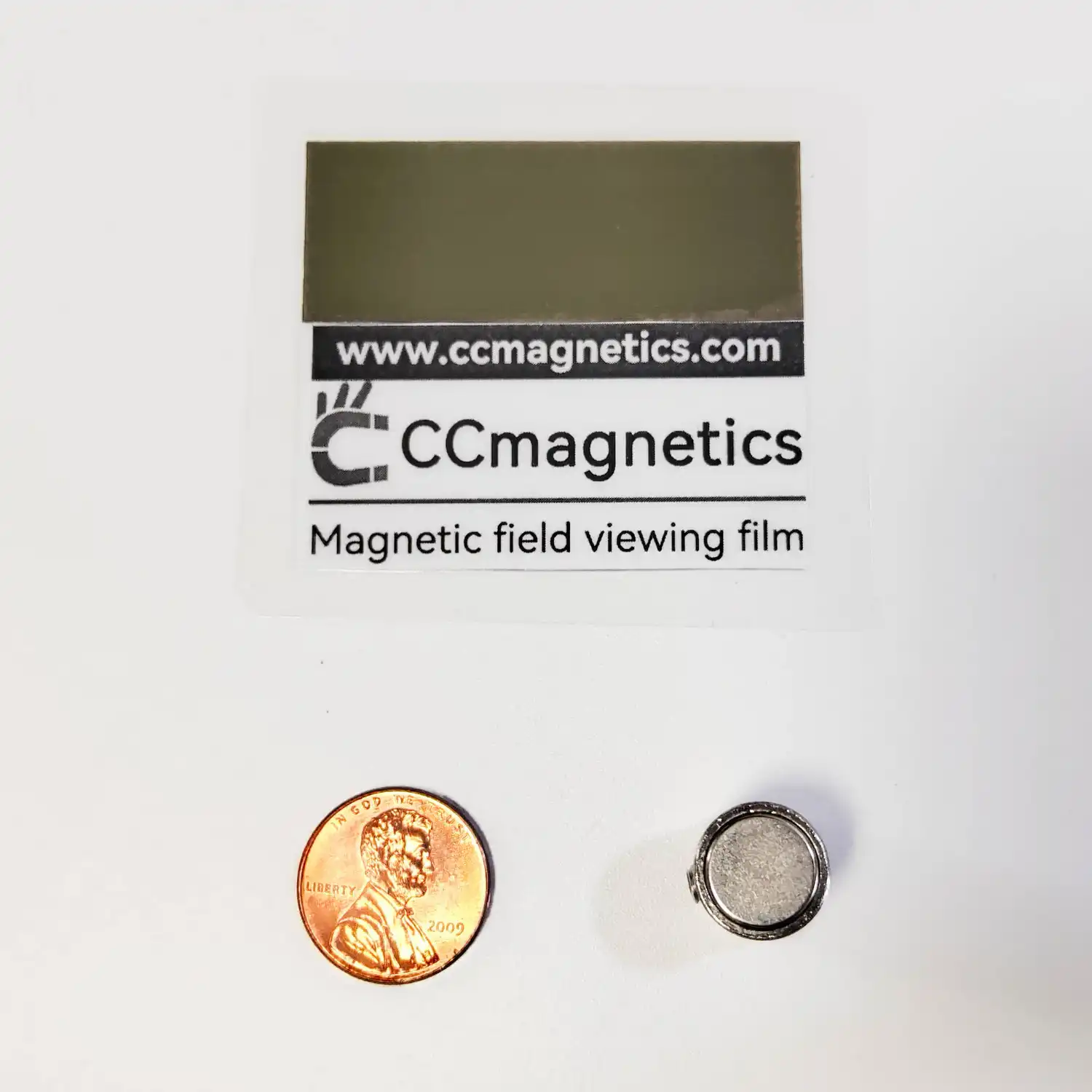

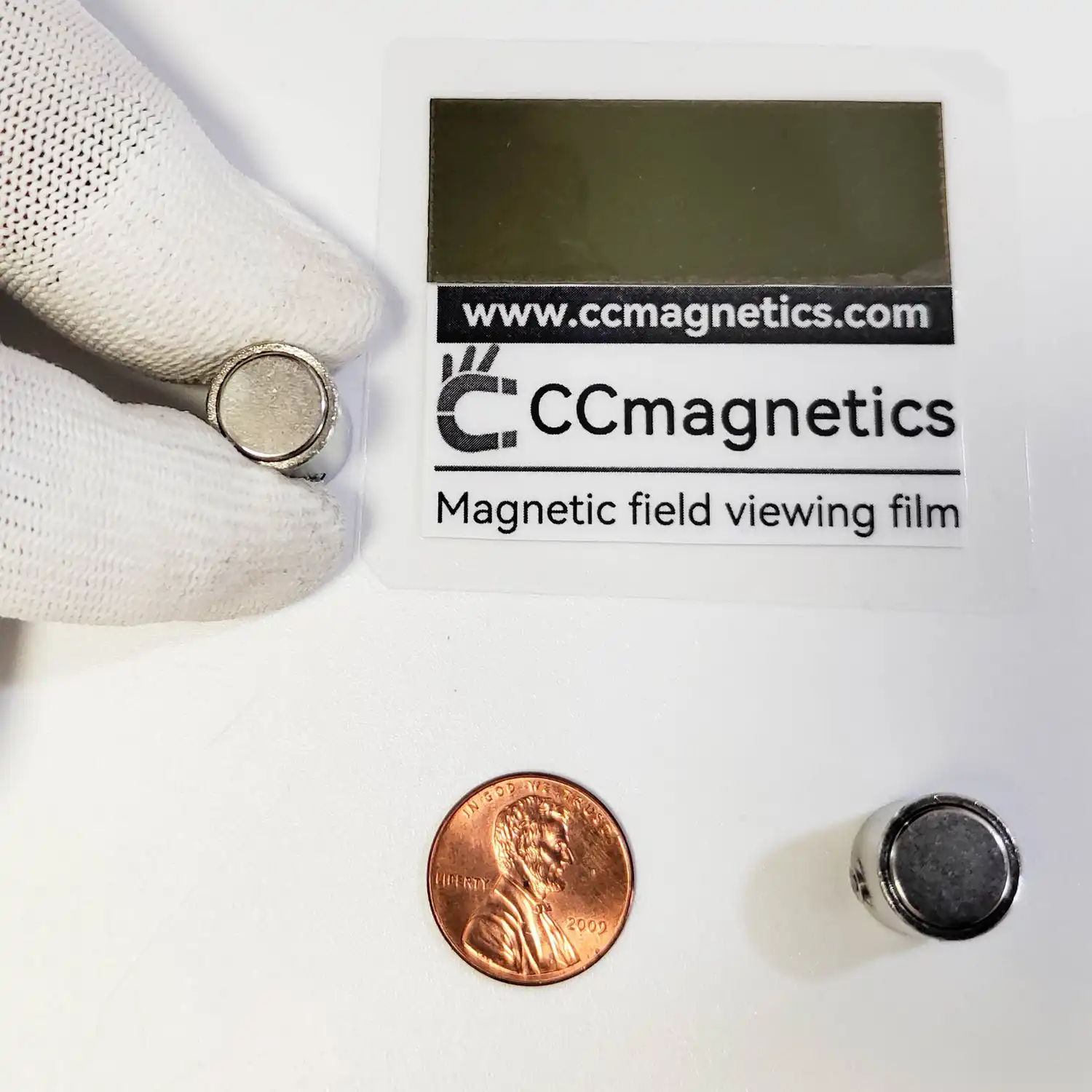

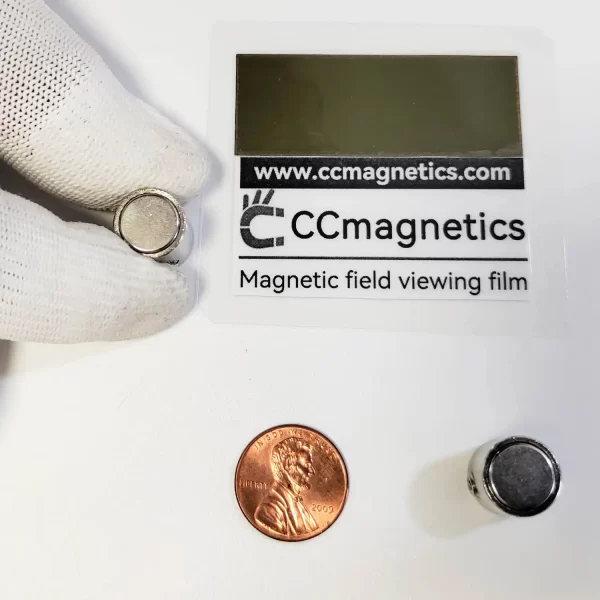

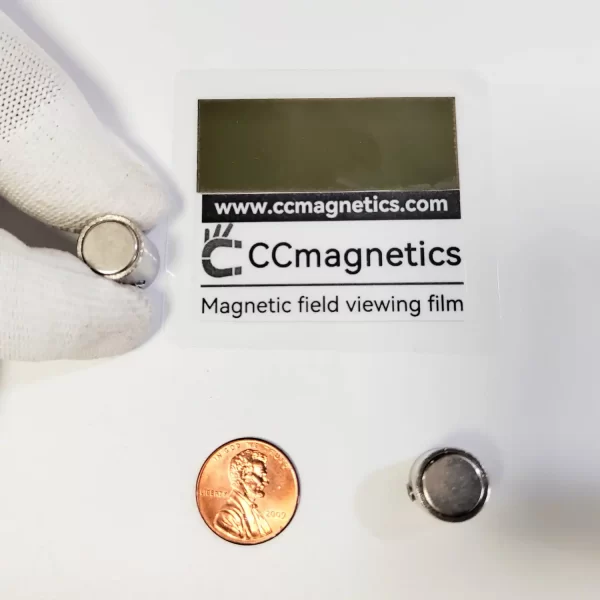

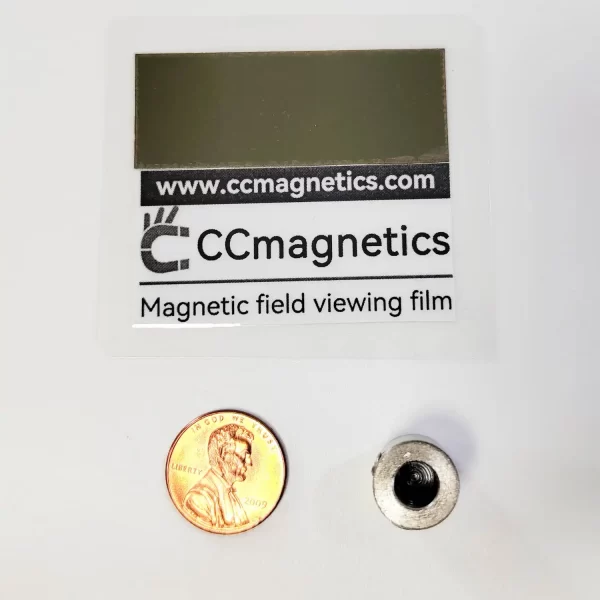

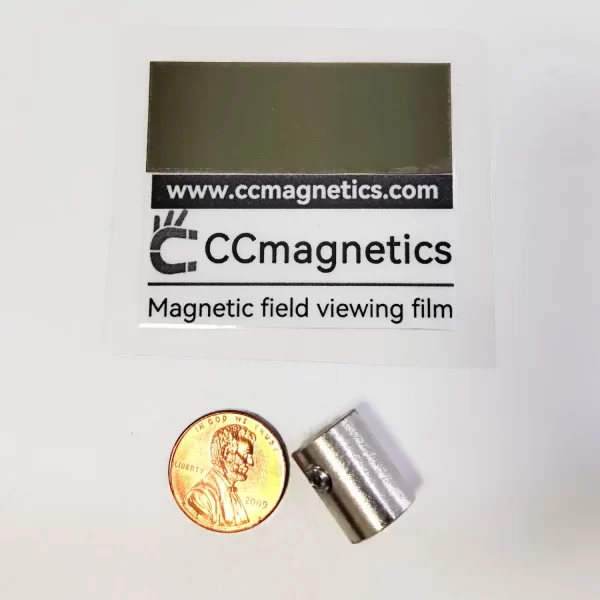

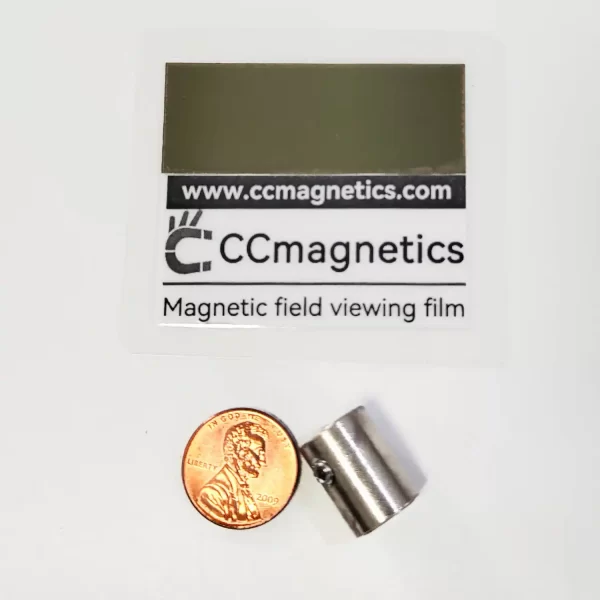

Ideal for sensitive applications like lab instruments, medical devices, and micro-machinery,Magnetic Disk Coupler,Magnetic Coupled Pump,Magnetically Coupled Pumps,Magnetically Coupled Pump,Magnetic Pump Coupling,Face to Face Torque Magnetic Coupling

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

Advantages and Disadvantages of Aluminum Magnetic Disc Coupling

- Advantages

- Lightweight and strong

- Excellent corrosion resistance

- Good thermal conductivity

- Easily machinable and weldable

- Disadvantages

- Less strong than steel

- Can be susceptible to stress corrosion cracking

- Not as hard as some other metals

What is Magnetic Disc Coupling?

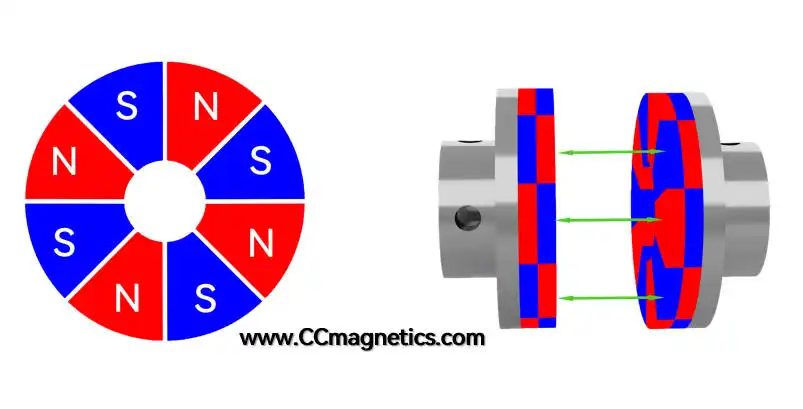

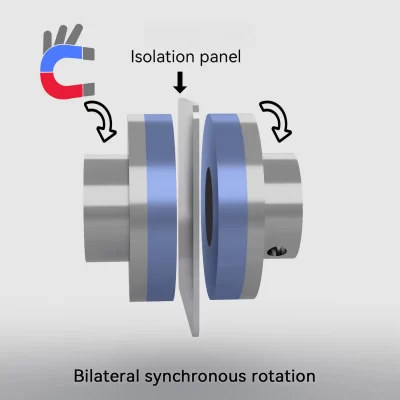

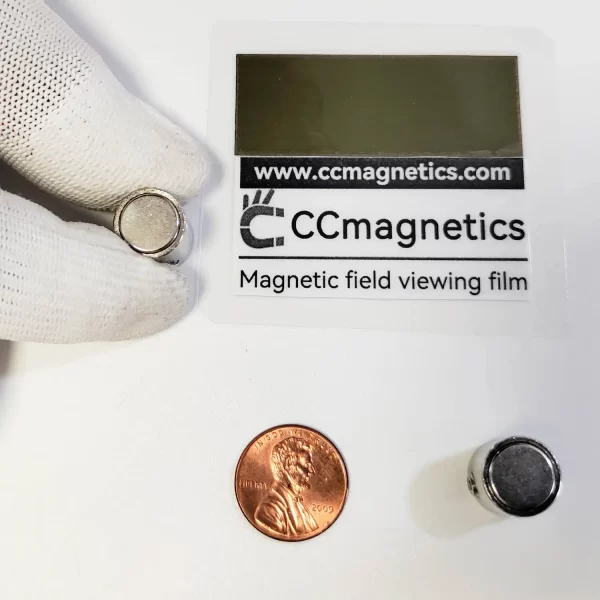

Magnetic Disc Coupling provide a contactless means of torque transfer. They are predominantly utilized in pumps for applications requiring seal-less operation, thereby preventing the escape of corrosive, toxic, or flammable liquids into the atmosphere.

The concept is straightforward: Opposite poles attract. This fundamental principle enables the transmission of torque from one magnetic hub to another. By rotating one magnetic hub, the torque is magnetically conveyed to the companion hub. This transmission can occur through air or via a non-magnetic barrier like stainless steel or fiberglass, achieving complete isolation of the inner from the outer hub. The design excludes any contacting components.

Understanding Magnetic disk coupler

Parameter

| PN | B | SCM | SFM | MC | HS | RPM | Tq1 (N.m) | Tq5 (N.m) | A | C | D | E | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XD12 | 4~6 | S/L | A | F | B/T | 35,500 | 0.05 | - | 12 | 16 | 12 | - | M3 |

| XD24 | 6~10 | S/L/A | B/C/A | F/H | B/T | 35,000 | 0.42 | 0.04 | 24 | 18 | 18 | 10 | M4 |

| XD28 | 6~10 | S/L/A | B/C/A | F/H | B/T | 34,000 | 0.75 | 0.12 | 28 | 18 | 20 | 10 | M4 |

| XD32 | 8~12 | S/L/A | B/C/A | F/H | B/T | 32,000 | 1.95 | 0.32 | 32 | 18 | 24 | 10 | M5 |

| XD43 | 12~20 | S/L/A | B/C/A | F | B/T | 26,500 | 3.8 | 1.2 | 43 | 20 | 30 | 12 | M5 |

| XD50 | 12~20 | S/L/A | B/C/A | F | B/T | 23,000 | 4.2 | 1.5 | 50 | 22 | 34 | 13 | M5 |

| XD68 | 15~25 | S/L/A | B/C | F | B/T | 17,500 | 16.2 | 7.8 | 68 | 30 | 40 | 18 | M5 |

| XD78 | 18~30 | S/L/A | B/C | F | B/T | 15,000 | 18.5 | 10 | 78 | 32 | 42 | 18 | M5 |

| XD90 | 20~35 | S/L/A | B/C | F | B/T | 13,500 | 22.8 | 8.7 | 90 | 38 | - | 20 | M6 |

| XD100 | 20~35 | S/L/A | B/C | F | B/T | 12,000 | 28.5 | 10.5 | 100 | 40 | - | 22 | M6 |

| XD120 | 28~38 | S/L/A | B/C | F | B/T | 10,000 | 33 | 12.3 | 120 | 50 | - | 30 | M8 |

| XD130 | 35~40 | S/L/A | B/C | F | B/T | 9,000 | 50 | 19.6 | 130 | 45 | - | 25 | M8 |

| XD38 | 8~15 | S/L/A | B/C/A | F/H | B/T | 30,000 | 2.98 | 0.82 | 38 | 18 | 28 | 10 | M5 |

| XD63 | 15~25 | S/L/A | B/C | F | B/T | 20,000 | 11 | 4.5 | 63 | 25 | 36 | 15 | M5 |

| PN | B | SCM | SFM | MC | HS | RPM | Tq1 (in. lbs) | Tq5 (in. lbs) | A | C | D | E | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XD12 | 0.16~0.24 | S/L | A | F | B/T | 35,500 | 0.4 | - | 0.47 | 0.63 | 0.47 | - | M3 |

| XD24 | 0.24~0.39 | S/L/A | B/C/A | F/H | B/T | 35,000 | 3.7 | 0.4 | 0.94 | 0.71 | 0.71 | 0.39 | M4 |

| XD28 | 0.24~0.39 | S/L/A | B/C/A | F/H | B/T | 34,000 | 6.6 | 1.1 | 1.1 | 0.71 | 0.79 | 0.39 | M4 |

| XD32 | 0.31~0.47 | S/L/A | B/C/A | F/H | B/T | 32,000 | 17.3 | 2.8 | 1.26 | 0.71 | 0.94 | 0.39 | M5 |

| XD38 | 0.31~0.59 | S/L/A | B/C/A | F/H | B/T | 30,000 | 26.4 | 7.3 | 1.5 | 0.71 | 1.1 | 0.39 | M5 |

| XD43 | 0.47~0.79 | S/L/A | B/C/A | F | B/T | 26,500 | 33.6 | 10.6 | 1.69 | 0.79 | 1.18 | 0.47 | M5 |

| XD50 | 0.47~0.79 | S/L/A | B/C/A | F | B/T | 23,000 | 37.2 | 13.3 | 1.97 | 0.87 | 1.34 | 0.51 | M5 |

| XD63 | 0.59~0.98 | S/L/A | B/C | F | B/T | 20,000 | 97.4 | 39.8 | 2.48 | 0.98 | 1.42 | 0.59 | M5 |

| XD68 | 0.59~0.98 | S/L/A | B/C | F | B/T | 17,500 | 143.4 | 69 | 2.68 | 1.18 | 1.57 | 0.71 | M5 |

| XD90 | 0.79~1.38 | S/L/A | B/C | F | B/T | 13,500 | 201.8 | 77 | 3.54 | 1.5 | - | 0.79 | M6 |

| XD78 | 0.71~1.18 | S/L/A | B/C | F | B/T | 15,000 | 163.7 | 88.5 | 3.07 | 1.26 | 1.65 | 0.71 | M5 |

| XD100 | 0.79~1.38 | S/L/A | B/C | F | B/T | 12,000 | 252.2 | 92.9 | 3.94 | 1.57 | - | 0.87 | M6 |

| XD120 | 1.1~1.5 | S/L/A | B/C | F | B/T | 10,000 | 292.1 | 108.9 | 4.72 | 1.97 | - | 1.18 | M8 |

| XD130 | 1.38~1.57 | S/L/A | B/C | F | B/T | 9,000 | 442.5 | 173.5 | 5.12 | 1.77 | - | 0.98 | M8 |

Parameter Notes:

| Term | Explanation | Notes |

|---|---|---|

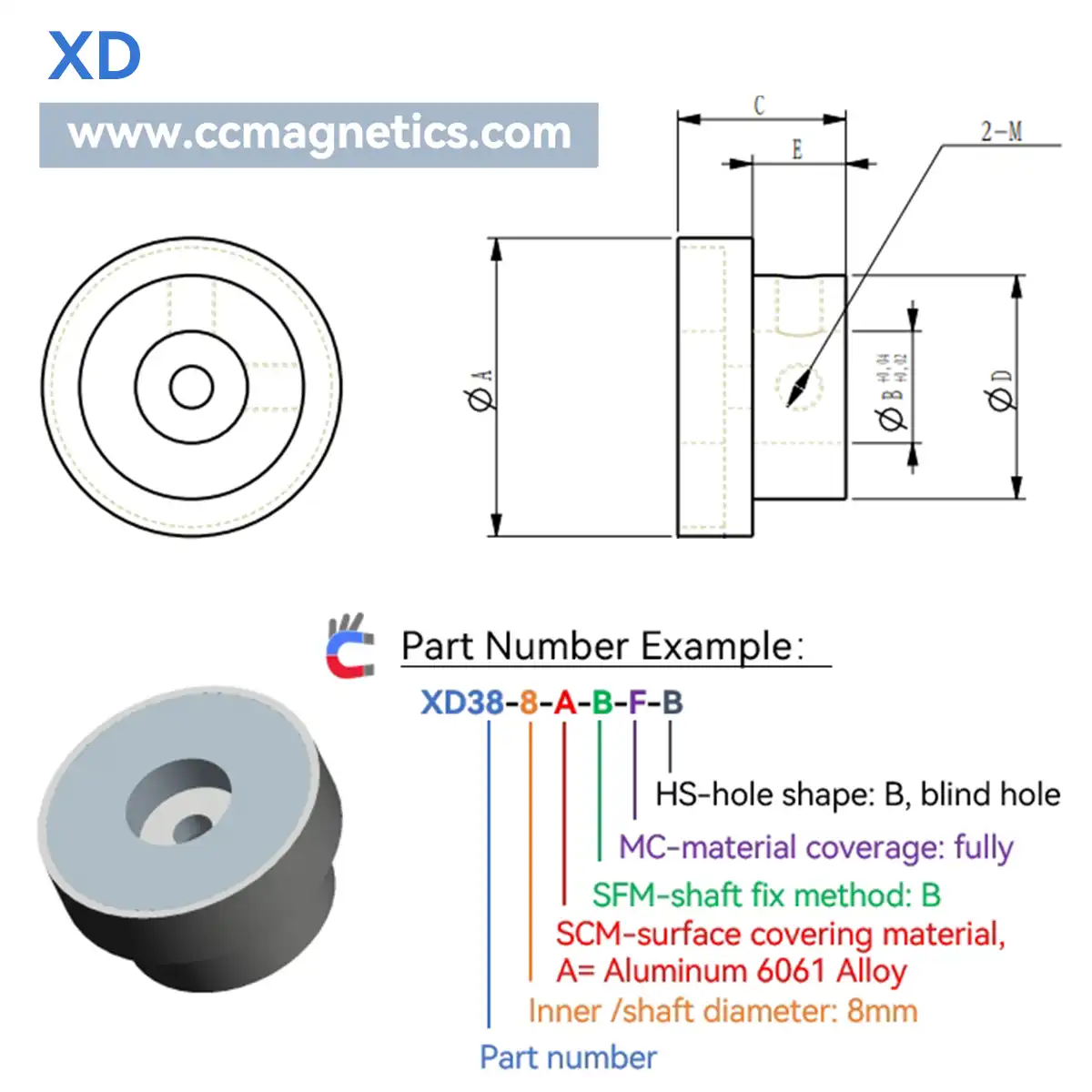

| SCM | Surface Covering Material | A=Aluminum 6061 Alloy (UNS A96061), |

| S=Stainless Steel 304 (UNS S30400), | ||

| L=Stainless Steel 316 (UNS S31600), | ||

| T=TC4 Titanium Alloy, Ti-6Al-4V, (UNS R56400). | ||

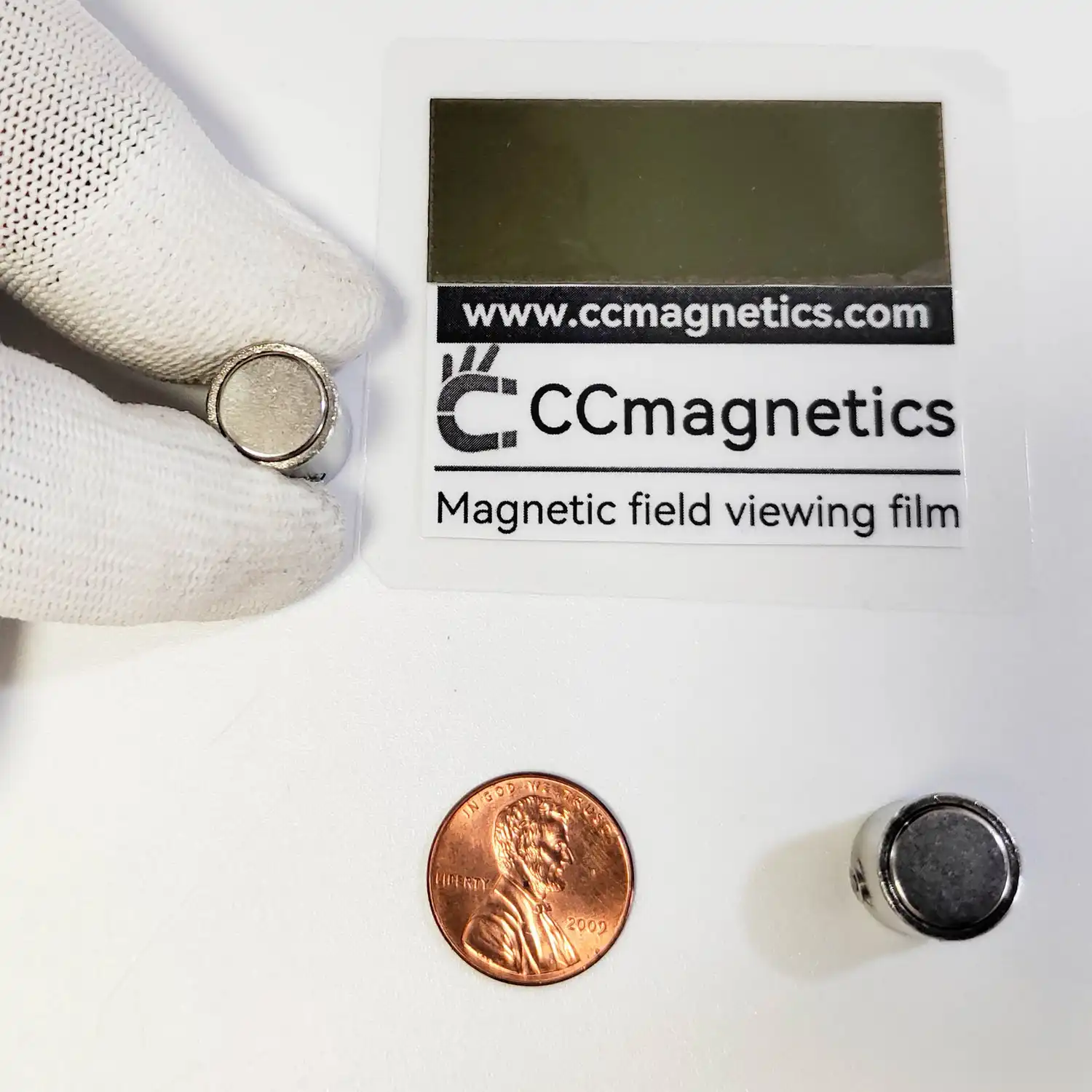

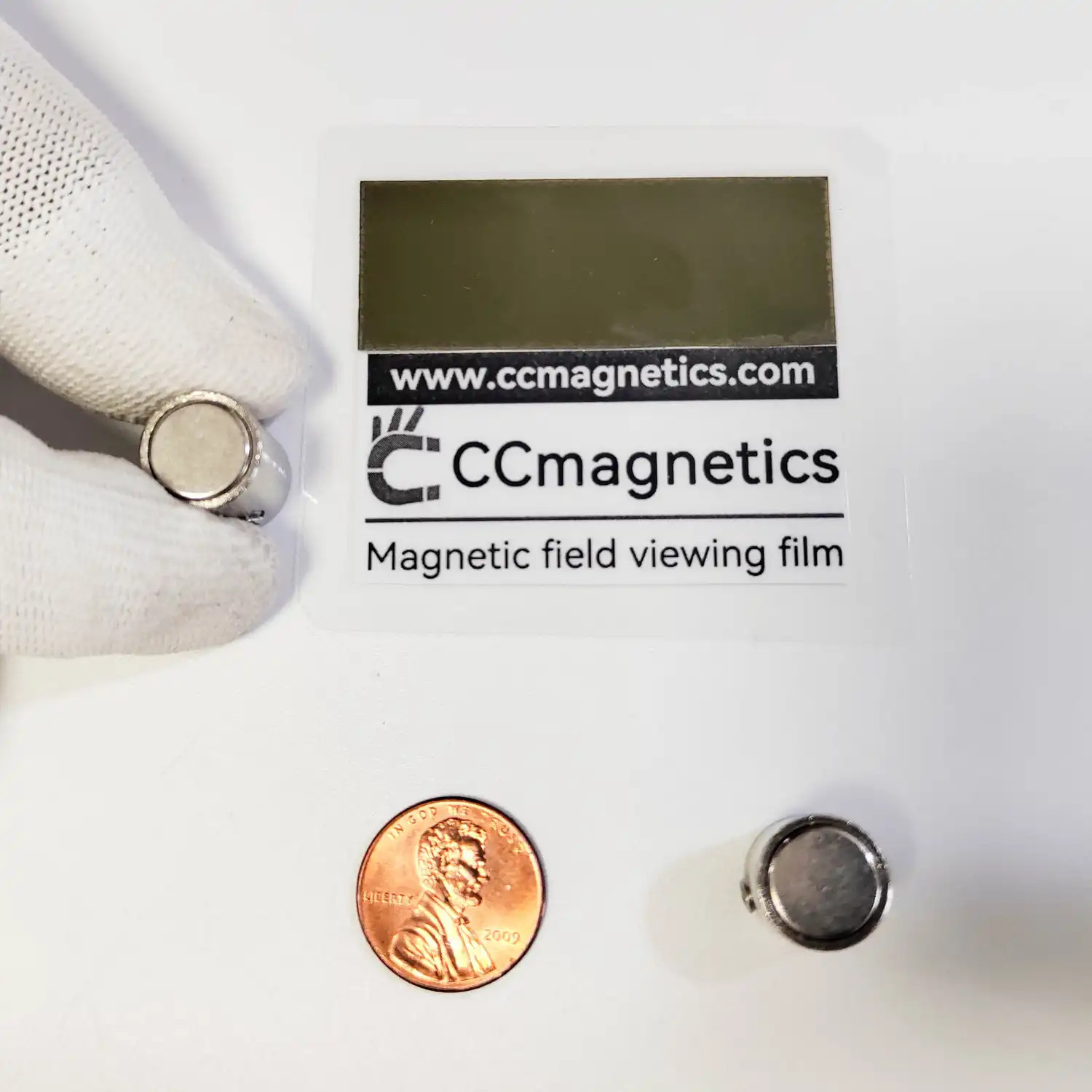

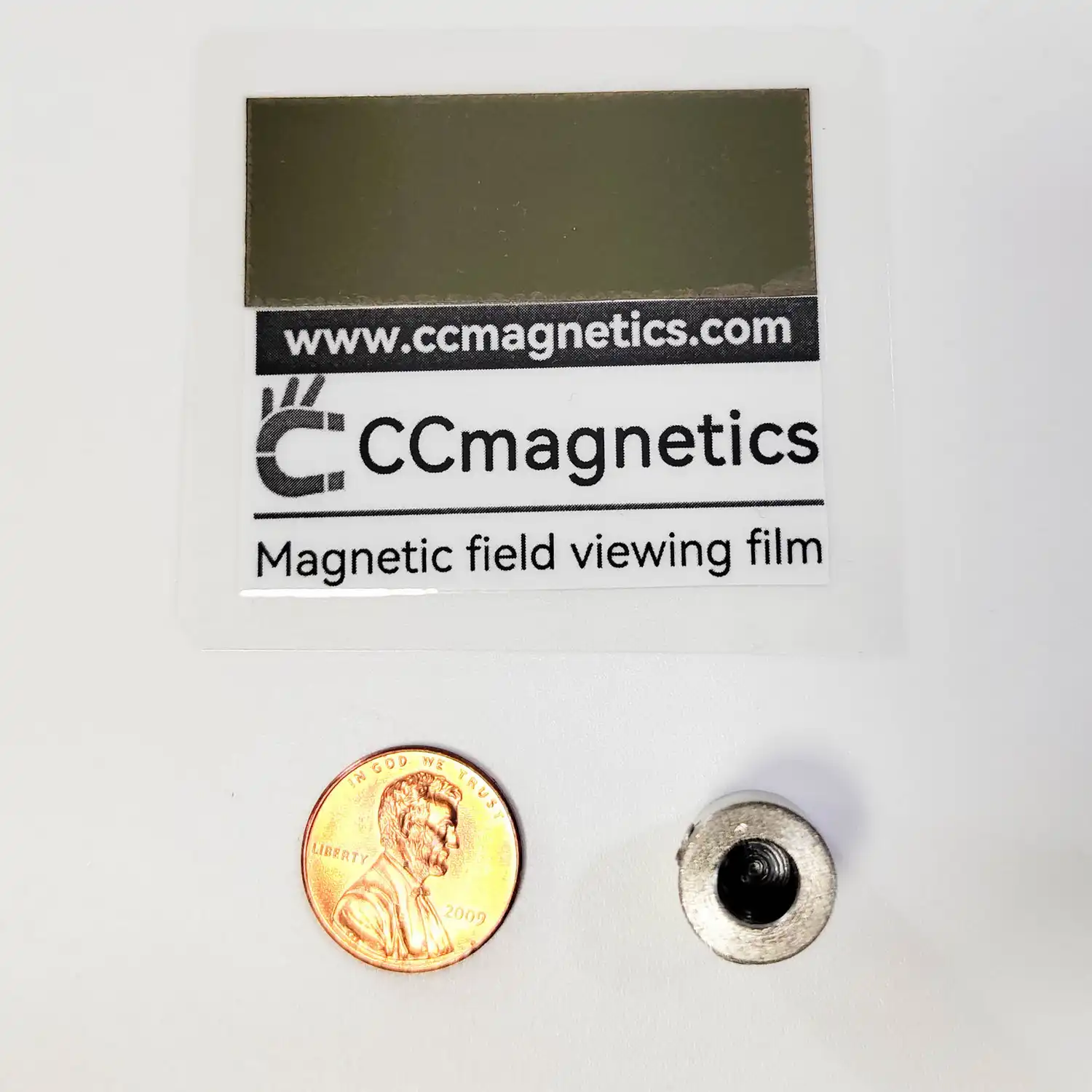

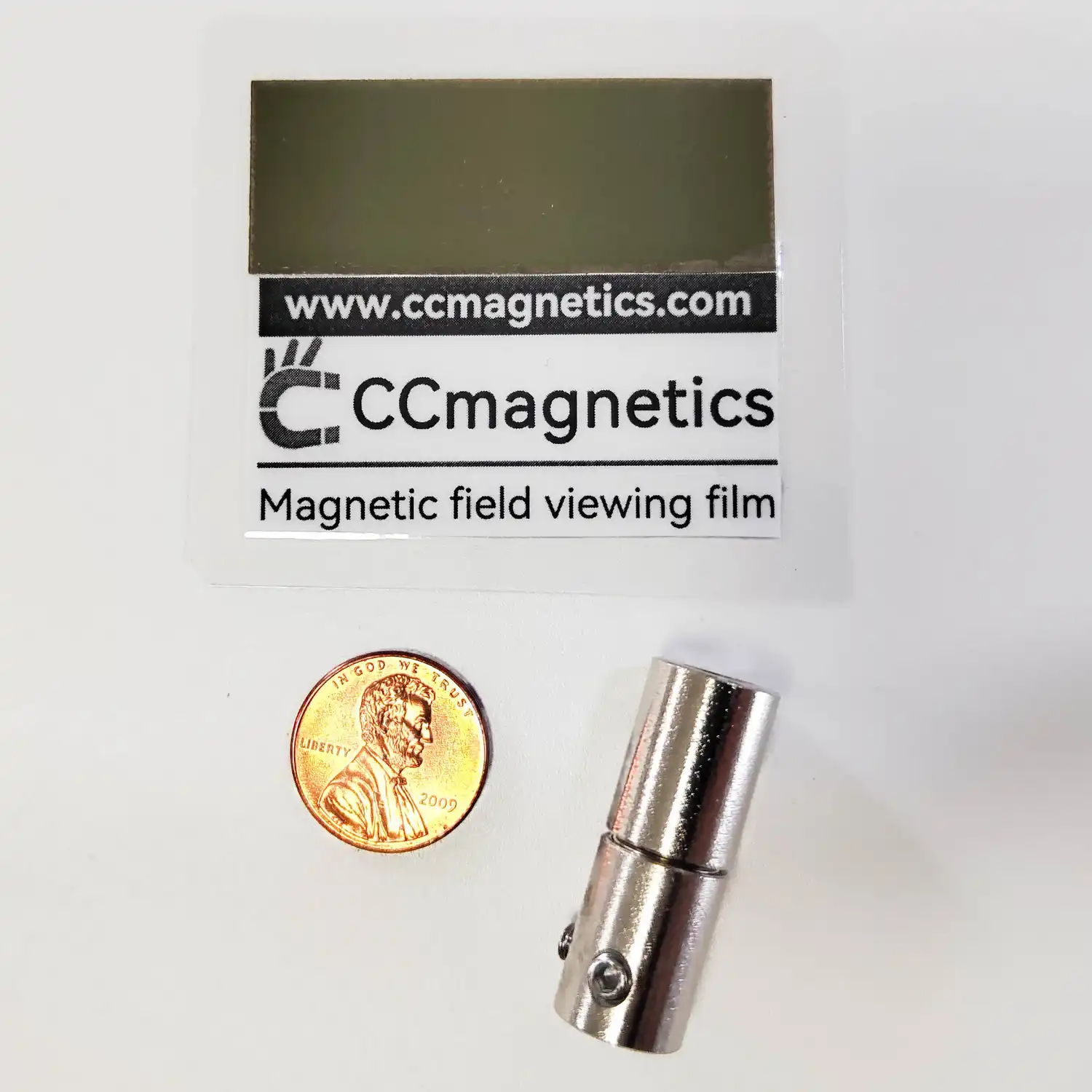

| SFM | Shaft Fixing Method | A,B,C, refer to the picture for details. |

| MC | Material Coverage | F= Fully, H= Half |

| HS | Hole Shape | B= Blind hole, T=Through hole |

| RPM | RPM, Revolutions Per Minute | Max speed, Revolutions Per Minute |

| Tq1 | Torque, gap = 1mm / 0.03in | The torque value shown is for a 1mm or 0.03in gap. |

| Tq5 | Torque, gap = 5mm / 0.2in | The torque value shown is for a 1mm or 0.03in gap. |

Advantages of magnetic disk coupler

- Very low noise and vibration

- No wear No dust

- No heat generation

- Oil-free

- Power transmission through wall

- Torque limiter function

- Easy attaching and detaching

- Large tolerance for declination and eccentricity

Magnetic disc vs co-axial coupling comparison

| Magnetic disc vs co-Axial coupling comparison |

|

|

|---|---|---|

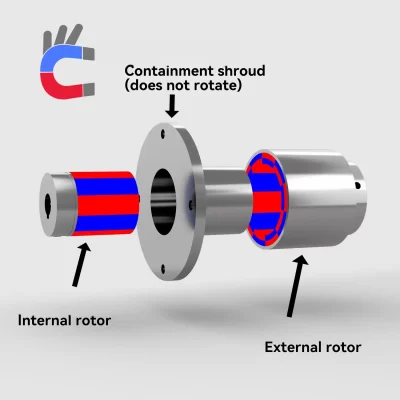

| Coupling style | Magnetic disc couplings ( XD ) | Co-axial magnetic couplings ( XC ) |

| Permanent-magnetic | √ | √ |

| Contactless | √ | √ |

| Maintenance-free | √ | √ |

| Torsionally flexible | √ | √ |

| Low vibrations | √ | √ |

| Material | Standard: SS304. Options: Aluminum alloy 6061,Stainless steel 316L,PVC, available) |

Standard: SS304. Options: SS316/UNS S31603. |

| Containment shroud | None | Optional |

| Axial forces | High axial force which must be restrained | Coupling finds its own center with ~0 axial force |

| Shaft fixing method | Small size type A, big size type B & C available |

Type B |

| Slip torque adjustment | Air gap can be adjusted to increase or decrease slip torque |

Coupling hubs can be seperated axially to decrease slip torque (axial force will result) |

| Angular misalignment capacity | 3° Max | Ensure coupling hubs (or barrier if used) do not contact |

| Parallel misalignment capacity | 6.35mm (0.25in) Max | Ensure coupling hubs (or barrier if used) do not contact |

| Containment barrier | Simple flat barrier | Top-hat shaped barrier |

| Max. pressure resistance [bar] | Up to 80 bars depending on size | Up to 90 bars depending on size |

| Max. temperature resistance [°C] | 150/300 depending on magnet material | 150/300 depending on magnet material |

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

Reviews

There are no reviews yet.