This article sorts out the development status of electric vehicle motors, and describes and summarizes them from different directions according to the typical motor design and application progress of more than 50 electric vehicle motors that have been mass-produced. From the perspective of motors, the main research and development status can be summarized as follows:

Motor Type Permanent Magnet

Permanent magnetization has become a standard configuration in the industry, and the research and development and application of electric excitation and induction motors are gradually increasing. In addition, the research and development of some special motors is also ongoing. Such as switched reluctance motors, axial motors, rare earth-free permanent magnet motors, etc. For all kinds of pure electric and hybrid new energy vehicles currently on the market, permanent magnet synchronous motors account for the majority, and induction motors account for a small part. Compared with permanent magnet synchronous motors, AC induction motors are larger in size, but the price is moderate, but induction motors can be made with high power and there is no demagnetization problem, so some large cars or electric cars that pursue performance, such as Tesla Model S And Weilai ES8, both use induction motors. Generally speaking, permanent magnetization is one direction, but induction motors still have their place in high-power and high-speed applications.

Other types of motors are mainly used in special vehicles

Switched reluctance motors: Turntide Technologies has overcome many of the problems with these motors by placing sensors in the motors to track rotor motion. Engineers use machine learning algorithms to determine the correct time to switch current. Engineers have designed a sensorless switched reluctance motor that minimizes vibration.

Axial Flux Motors: Products from Magnax Belgium reduce motor weight, size and cost. They are designed to minimize the air gap between the rotor and stator teeth. The motor uses the SRS method, with two rotors, each located on one side of the stator. In this configuration, the stator supports the electromagnetic gear, but does not act as a support or yoke for the rotor. The yoke is a steel cylinder that accounts for two-thirds of the mass of the station. Without the yoke, the motor could be significantly lighter, which the company estimates could increase the range of an EV by 7 percent.

Bi-Flux Motor: Another approach is taken by Linear Labs (Dallas-Fort Worth, Texas, USA), which opted to combine axial and radial flux designs in one motor. The company's "three-dimensional (3D) circumferential flux motor" consists of four rotors surrounding a stator. The central rotor spins inside the stator, while the second rotor spins outside the stator. The other two rotors are respectively located at the left and right ends of the stator, and there are 4 magnetic flux sources in total, and each rotor will generate torque in the direction of motion.

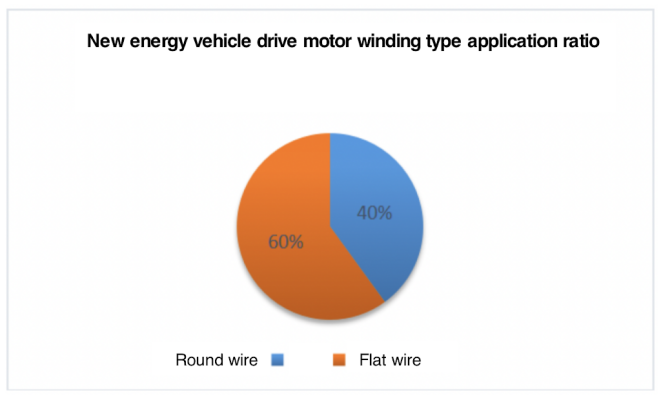

Flat Wire Motor or Round Wire Motor

The penetration rate of flat wire motors has increased rapidly. In 2021, Tesla will switch to domestic flat wire motors, which will greatly increase the penetration rate, and the trend of flat wire motors has been determined. Many potential explosive models use flat wire motors, and the penetration rate is expected to rapidly increase to 95% in 2025. Many high-end models are equipped with flat-wire motors. BYD's DMI models and e++ platform are all flat-wire motors. Volkswagen MEB, Weilai ET7, Zhiji L7, Jikr 001 and other star models use flat-wire motors.

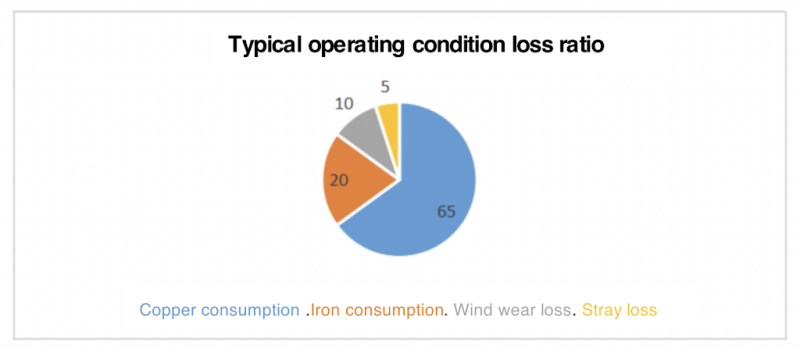

The flat wire motor can greatly improve conversion efficiency. In the WLTC working condition, the conversion efficiency of the flat wire motor is 1.12% higher than that of the traditional round wire motor; in the urban working condition (low speed and high torque), the difference in efficiency between the two is 10%. According to the calculation of a typical A-class car with a battery life of 500km (equipped with a 60kwh battery pack and a 150kw motor), under WLTC working conditions, the cost of batteries equipped with flat wire motors can save 672 yuan, and under urban working conditions, the cost of batteries can save 6,000 yuan.

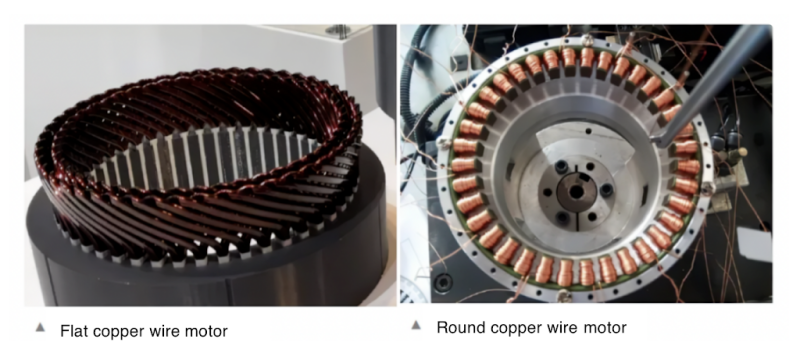

The slot full rate of flat wire is higher than that of round wire. When the slot full rate is higher, the copper wire required by the motor with the same power is shorter, and the resistance and heat generation are reduced. Theoretically speaking, the net slot full rate of the round wire is generally about 40%, while that of the flat wire can be increased to 70%. Since the cross section of the round wire is circular, there are inevitably irregular gaps between the wires, while the gap between the flat wires is smaller and the slot fill rate is higher. The high-efficiency range of flat-wire motors is much higher than that of round-wire motors. The high-efficiency range of round-wire motors generally requires that the range with efficiency > 85% account for no less than 85%, which is called "double 85". However, the efficiency of the flat wire motor > 90% accounts for no less than 90%, which is called "double 90". The efficiency of the motor is related to the speed and torque. The frequent start and stop conditions in the urban working conditions belong to the low speed and high torque working conditions, and this is the low efficiency range of the round wire motor, while the flat wire motor is in this working condition. The conversion efficiency is higher.

The flat wire motor has good heat dissipation performance: the temperature rise is 10% lower than that of the round wire motor. Due to the closer contact between the flat wire and the round wire, the heat dissipation is improved. It is found that the thermal conductivity between the windings under the high slot full rate is 150% of the low slot full rate. The winding has anisotropy in thermal conductivity, and the thermal conductivity in the axial direction is 100 times that in the radial direction. Under the condition of lower temperature rise, the whole vehicle can achieve better acceleration performance.

Low electromagnetic noise: the whole vehicle is quieter. The stress of the flat wire motor wire is relatively large, and the rigidity is relatively large. The armature has better rigidity, which can suppress the noise of the armature; the slot size can be relatively small, which can effectively reduce the cogging moment and further reduce the electromagnetic noise of the motor.

The small size brings high integration efficiency, which is in line with the development trend of all-in-one electric drives: due to the higher slot fill rate of flat wires, the amount of copper wires and corresponding stators of motors with the same power is less, and the volume is expected to decrease by 30%. In addition, because of the more advanced winding method, the flat wire motor brings easier cutting of the motor end, which reduces the end size by 15-20% compared with the round wire motor, further reduces the space, and realizes the miniaturization and light weight of the motor.

The large-scale application of flat wire motors also needs to overcome some shortcomings, such as low yield rate, slow speed increase, difficult standardization and patent barriers. In high-end models, in order to meet the pursuit of high performance, the number of matching flat wire motors has also begun to increase from the original single motor to dual motors. For example, Porsche's first pure electric sports car Taycan, and some models will even be equipped with three motors.

Insulated car-grade flat wires for new energy vehicles require high heat resistance, and mainly use polyesterimide wire enamel, polyamideimide wire enamel, and polyimide wire enamel with a temperature resistance of ≥180°C High temperature insulating materials are enamelled. Polyesterimide paint has good electrical properties and mechanical strength, and is resistant to thermal shock and softening breakdown. It is used as the main material of the primer coating in the manufacture of 180-level and above composite coated enameled wires, and is widely used in high-adhesion and Freon-resistant household appliances. Polyamide-imide paint has high heat resistance, not only has great hardness and non-softening properties of the paint film, but also has high adhesion to conductors. It was the first to be industrialized and can be used for a long time at 210°C. Coil windings for electrical and electronic components of high temperature resistant motors, used as insulating coating for magnet wires. Polyimide paint has excellent heat resistance, aging resistance and high voltage electrical breakdown resistance. It is mainly used in insulating varnish-coated magnet wires, or as a high-temperature resistant coating in the electrical industry, aerospace, oil pipelines, etc.

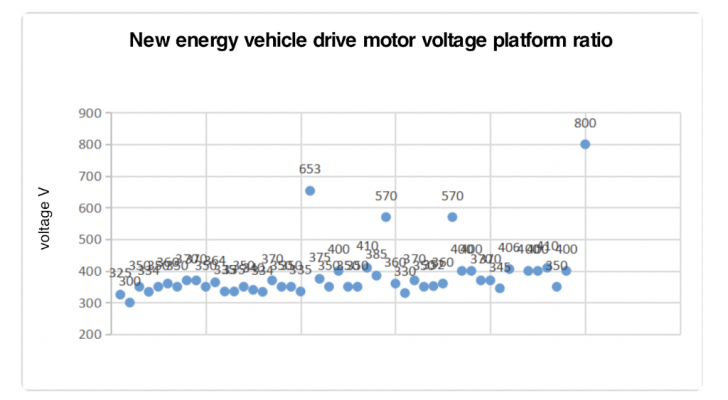

High Pressure

Advantages: 800V can significantly reduce the wire diameter of high-voltage wire harness, reduce heat generation, reduce quality, and save wire harness cost. The voltage level has increased from 400V to 800V. According to the simplest P=UI, in the case of the same output power, the current transmitted by the 800V system will be smaller, the cable diameter and weight can be reduced, and the cost and installation space of the wiring harness can be saved. .

Disadvantage: The probability of corona corrosion increases under the 800V platform, and corona corrosion will cause serious damage to the motor insulation. Corona discharge refers to the partial self-sustained discharge of a gas medium in an uneven electric field, and is the most common form of gas discharge. It usually occurs near the tip electrode with a small radius of curvature, such as at the exit of the winding, inside the insulation layer of the winding, etc. Corona is air gap discharge, part of the energy is converted into light, heat, sound, electromagnetic, etc., which will cause

1) Thermal effect local temperature rise, insulation aging, etc;

2) Mechanical damage, a large number of charged ions "electrons and positive and negative ions" collide with high energy and high speed, resulting in a decrease in the mechanical strength of the insulating layer, and insulation failure problems such as pits, pits, and holes in the insulating layer in the partial discharge area;

3) Chemical damage, partial discharge of gas forms ozone, which is unstable in chemical properties and easily generates nitrogen oxide, which reacts with water vapor to generate nitric acid, which corrodes the insulating layer.

Technical route: To meet the technical requirements of 800V, there are mainly two technical routes: 1) thick paint film process, 2) thin paint film + PEEK film package process; improving the thickness of the paint film is the simplest and most effective way, the insulation performance of the enameled wire Proportional to the thickness of the paint film, the structure of the current mainstream new energy flat wire is: the inner layer is a copper flat wire conductor. According to the performance requirements of the flat wire and the field of use, the copper flat wire conductor is coated with two or three layers of insulation The paint film specifically includes a primer layer, a corona-resistant paint layer and a top coat layer. The first layer is polyesterimide or polyamideimide paint film, the second layer is corona resistant paint film, and the third layer is polyamideimide or polyimide paint film.

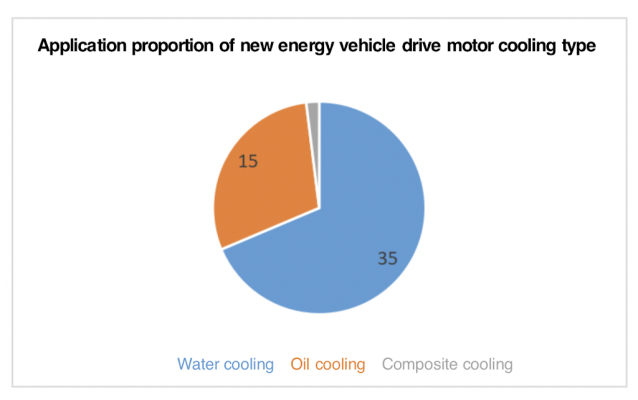

Various Forms of Cooling

The main cooling methods of motors are natural cooling, air cooling and liquid cooling.

In the application environment where the motor must be enclosed and protected, or there is no strong wind, the most commonly used method is internal oil cooling, such as the combination of oil cooling in the stator slot used by the high-speed motor designed by AVL. Some motors also use a combination of winding oil injection cooling + stator oil cooling + rotor oil cooling.

Liquid cooling form: When the motor cooling system is at a low temperature, the coolant pump does not work. After the temperature rises, the coolant pump works. The working temperature of the coolant pump should not exceed 75°C, and the most suitable working temperature should be lower than 65°C. The cooling system of the electric vehicle drive motor and controller mainly relies on the cooling water pump to drive the coolant to circulate in the cooling pipe. Through physical processes such as heat exchange in the radiator, the coolant takes away the heat generated by the motor and controller. In order to make the radiator heat dissipate more fully, a fan is usually also arranged behind the radiator. When the motor is working, there is always a part of the loss that is converted into heat. It must continuously dissipate heat through the motor casing and the surrounding medium. This process of dissipating heat is called cooling.

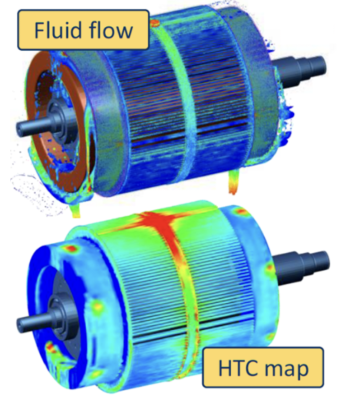

Key points of water channel design: when the cross-sectional size of the water channel increases, the cooling water flow rate will decrease, and the convective heat transfer coefficient of the water channel will also decrease. Due to the limitation of the mechanical strength of the cooling water jacket, the cross-sectional size of the water channel cannot be increased without limit; if the cross-sectional size of the water channel decreases Small, the cooling water flow rate will increase, its convective heat transfer coefficient will increase, but the flow resistance will also increase. As the cross-sectional size of the water channel increases, the flow rate of the cooling water will decrease, and the convective heat transfer coefficient of the water channel will also decrease. Due to the limitation of the mechanical strength of the cooling water jacket, the cross-sectional size of the water channel cannot be increased without limit; if the cross-sectional size of the water channel is reduced, the cooling water The flow rate will increase, and its convective heat transfer coefficient will increase, but the flow resistance will also increase. It can be seen that when designing the cooling water jacket, in addition to process implementation and cost factors, it is necessary to consider the analysis and calculation of the head loss of the cooling water jacket, the convective heat transfer in the water channel, and the mechanical stress of the entire water jacket. The heat flow simulation analysis software can be used to optimize the design of the cooling water jacket of the motor to achieve the best match between the best heat dissipation performance and the minimum pump power consumption.

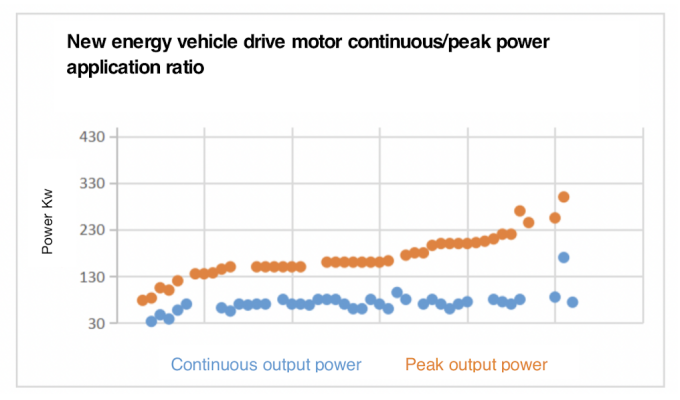

High Power

High power density, more powerful vehicle power. The power of the motor is positively correlated with the copper content. The slot fill rate of the flat wire motor is increased, and the copper wire filling amount is increased by 20-30% under the same volume. The output power is expected to increase by 20-30%, and the vehicle power is stronger. The maximum speed of foreign drive motors such as Volkswagen, Volvo, and Chrysler continue to increase, reaching a maximum of 14k~16krpm; from the perspective of winding structure, hairpin winding/flat wire winding (GM, Toyota, Honda, Daimler, etc.) has become a clear technology One of the directions, the power density of motors reaches above 3.8~4.5kW/L; no/low-weight rare earth materials have begun to be applied. At the national policy level, high motor power density is advocated. The "Thirteenth Five-Year Plan" proposes that the power density of new energy passenger car motors should meet 4.0kw/kg, which is higher than the current level of about 3.5kw/kg for round wire motors. At present, when the power density of round wire motors has entered a difficult mode, the development of flat wire motors is an inevitable way. According to the announcement of Moen Electric, the current power density of flat wire motors of leading companies is about 4.5kw/kg. The motor power density index of the US DOE2025 is greater than or equal to 5.7kW/kg. British Equipmake claims to develop a record-breaking motor with a peak power density of 20kW/kg. But after a few rounds of trying, the first electric motor, called the APM120, weighed just 14 kg and had a peak power of 125 kW at 12,000 rpm. Additionally, continuous power is rated at 75kW and peak torque is 130Nm. The calculation shows that the power density is about 9 kW/kg. The second, more powerful electric motor, called the APM 200, weighs 40 kg and delivers a peak power of 220 kW at 10,000 rpm. In addition, continuous power is 110 kW and peak torque is 450 Nm. The calculation shows that the power density is about 5.5 kW/kg.

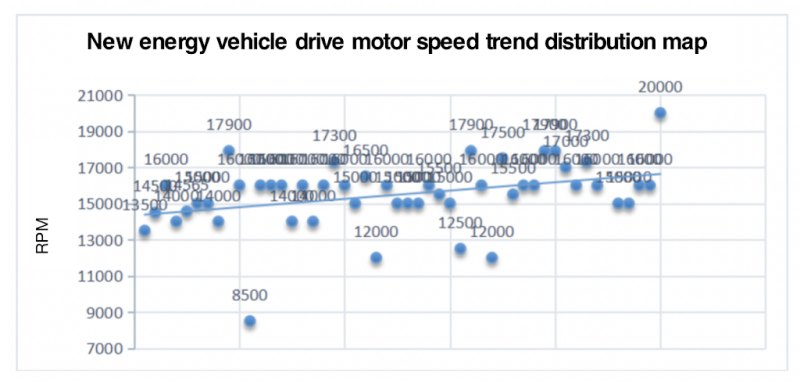

High Speed

Under the constraints of constant output torque and power of the electric drive assembly, by increasing the maximum speed of the drive motor and reducer, reducing the volume and weight of the motor, and increasing the power density level. Volkswagen, Volvo, Chrysler and other foreign auto companies reduce the size and weight of motors by continuously increasing the motor speed. The motors of the Volkswagen Modular Electric Drive Platform (MEB platform) reach a maximum of 16,000rpm, and the maximum speed requirements of Volvo and Chrysler motors reach 14,000rpm. Tesla The maximum speed of the Model3 drive motor reaches 17900rpm. The overall technology of drive motor power density and efficiency in my country has improved rapidly, and the technical level is comparable to that of similar foreign products. The weight ratio of power of drive motors has reached above 4.0kW/kg. 15000rpm upgrade to 18000rpm or even 20000rpm above. However, problems such as heat dissipation, rotor structure, vibration and noise, high-efficiency design, and bearings brought about by high speed have to be solved. The centrifugal stress that the rotor structure of the high-speed motor must overcome generally adopts a metal sheath, the structure of the rotor itself, etc. in the range of "high speed", and uses carbon fiber winding in the range of more than 18,000.