Rare earth is known as "industrial gold". It can be combined with other materials to form a wide variety of new materials with different properties, which can greatly improve the quality and performance of other products. With the decline of China's rare earth reserves in the world's total reserves, rare earths have become a national strategic reserve resource; rare earths will cause environmental damage in the process of mining and deep processing.

The motor development is like this:

In 1822, Faraday proved that electricity can be converted into rotational motion;

With the continuous practice of this theory, the first DC generator and motor in human history came out;

Siemens used it to drive vehicles, and then created the world tram;

Edison also experimented with this motor, which greatly released the horsepower of the electric car.

Today, motors have become one of the indispensable components of mechanical equipment. However, traditional motor manufacturing is "inseparable from rare earths". In the motor manufacturing industry, energy conservation and emission reduction are urgently needed.

"As the environment changes, we begin to realize that the responsibility of an enterprise is not only to master the core technology, but also to combine the product with the environment and the needs of human survival. Only the products produced in this way are truly valuable." Well-known domestic business people say so.

Therefore, a synchronous reluctance motor that does not need to use permanent magnets, does not rely on rare earth elements, saves manufacturing costs, avoids environmental pollution from the development of rare earth mineral deposits, and fundamentally responds to the national call for energy conservation and emission reduction has emerged as the times require.

Synchronous reluctance motor that "stands out"

Synchronous reluctance motors have reluctance properties, follow the operating principle that the magnetic flux is always closed along the path of the least reluctance, and form torque through the magnetic pull generated by the reluctance changes caused by the rotor at different positions, relying on high performance and low cost, Energy-saving advantages stand out among many motor categories.

Synchronous reluctance motor VS traditional DC motor: no brushes and rings, simple and reliable, easy maintenance;

Synchronous reluctance motor VS traditional AC asynchronous motor: there is no winding on the rotor, so there is no rotor copper loss, which improves the efficiency of the motor;

Synchronous reluctance motor VS switched reluctance motor: the surface of the rotor is smooth and the change of reluctance is relatively continuous, which avoids the problems of torque ripple and large noise during the operation of the switched reluctance motor; at the same time, the stator has a sine wave magnetic field, which is easy to control and the hardware platform Mature, thereby reducing the cost of the drive control system;

Synchronous reluctance motor VS industrial darling - permanent magnet synchronous motor: there is no permanent magnet on the rotor, the cost is lower, and the problem of no weak magnetic field and loss of magnetic field is solved. Long-term use, the efficiency is more stable, and there are no strict requirements on volume and weight. Occasions can completely replace the permanent magnet synchronous motor.

Taking social responsibility with "black technology"

Independent research and development, the first to master the core technology of synchronous reluctance motors in China, and the use of special materials, multiple optimized motor control strategies, iron core manufacturing, motor assembly and other manufacturing processes, and finally unearthed more possibilities.

1. Energy saving and environmental protection

The synchronous reluctance motor cancels the permanent magnet, does not have the problem of high temperature loss of magnetism, and can operate stably at high temperature. Since it does not need to use permanent magnets, it does not rely on rare earth elements, saves manufacturing costs, and avoids environmental pollution caused by the development of rare earth deposits. It fundamentally responds to the national call for energy conservation and emission reduction. In addition, the synchronous reluctance motor rotor does not need to be cast aluminum, which greatly reduces energy consumption in the manufacturing process.

2. Efficient operation

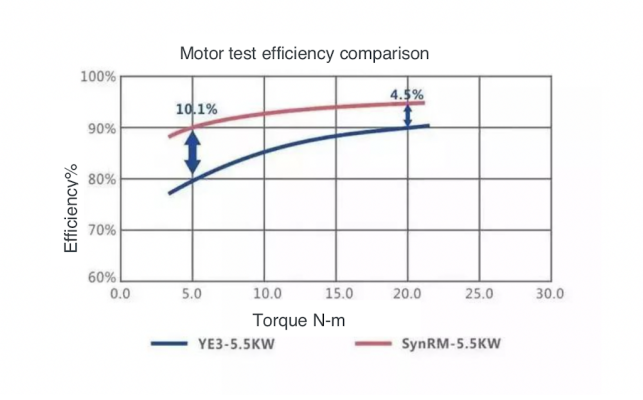

Compared with asynchronous motors, synchronous reluctance motors are more efficient, and can reach energy efficiency above IE4. They are all in the high-efficiency zone from 25% to 120% of the load range. When replacing asynchronous motors or YVF motors with the same power, the energy efficiency of the system can be greatly improved, and comprehensive power saving can be achieved. The effect is as high as more than 30%.

3. Quick response

Because there are no squirrel cage guide strips and magnetic steel on the rotor, and the large-area magnetic barrier slots on the rotor punching plate, the rotor of the synchronous reluctance motor has a small moment of inertia. Under the same specifications, the moment of inertia of synchronous reluctance motors is only about 30% of that of asynchronous motors. For occasions that require high acceleration response capabilities, such as extruders, the requirements for motor overload multiples can be significantly reduced, and the specifications of inverter current modules can be reduced, saving energy. user costs while speeding up production efficiency.

4. Good versatility

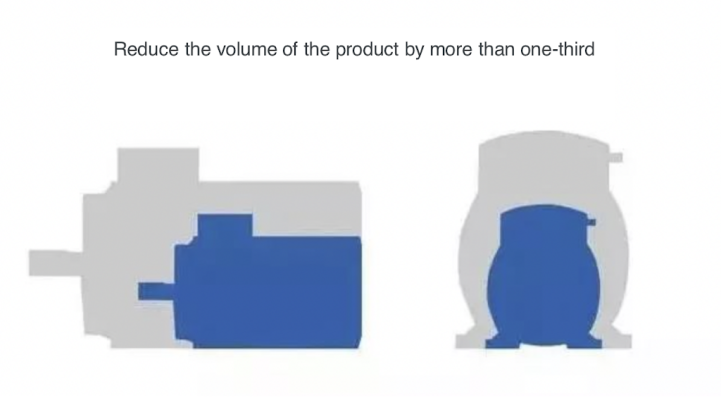

Synchronous reluctance motors use IEC standard housings (cast aluminum or cast-iron housings can be used according to user needs), and the installation dimensions refer to IEC standard housings. For high power density synchronous reluctance motors, because the frame size is 1-2 frame sizes smaller than the standard three-phase asynchronous motor, the volume is reduced by more than 1/3, which can be customized according to customer needs (multiple installation methods, External device interface design), directly replace the original motor.

5. Low temperature rise

Because the synchronous reluctance motor still maintains a small rotor loss when it is running at rated power, the temperature rise margin is large. It can maintain constant torque operation in the range of 10%-100% rated speed, and can allow 1.2 times overload operation, which is also suitable for self-fan cooling structure.

6. High reliability and easy maintenance

The rotor has no risk of demagnetization, low loss, and low bearing temperature, ensuring the long-term stability of the bearing replacement system and increasing the life of the insulation system; at the same time, the rotor is light in weight, easy to disassemble, and safer to maintain. Easily cope with harsh environments and extreme operating temperatures.

In addition, in pumps, fans and other applications that require partial rated load operation, synchronous reluctance motors are extremely in line with user needs for energy saving and emission reduction.

At present, there are more than 20 patents on the synchronous reluctance motor body and control technology, and a large number of products have been realized, and the technical indicators exceed international competition products.

Some experts once asked: "China does not have the problem of rare earth safety. Should it be consistent with the international level and use synchronous reluctance motors to take the route of 'removing rare earth technology'? Or make full use of the advantages of rare earths to improve the cost performance of products?" "Let the sky Bluer, the earth greener", constantly working on synchronous reluctance motor technology, pursuing excellence, because energy saving and emission reduction is not only a national issue, it is more related to every life on the earth.