China is the country with the largest reserves of rare earths in the world. Deng Xiaoping once said that "there is oil in the Middle East, and China has rare earths." Rare earth is known as the "vitamin" of modern industry. It has important strategic value in intelligent manufacturing, new energy industry, military field, aerospace, medical treatment and all emerging industries related to the future. In February 1984, after more than 120 days and nights of continuous hard work, the research and development team of Zhongke Sanhuan successfully developed China's first NdFeB rare earth permanent magnet material with a magnetic energy product of 38 megawatts. This marks that China has officially become one of the few countries in the world that has developed the third-generation rare earth permanent magnet materials!

The third-generation rare earth permanent magnet NdFeB is the most powerful permanent magnet among contemporary magnets, and is known as the "permanent magnet king". NdFeB is the strongest magnetic material among the magnetic materials found in the world. Its magnetic performance is 10 times higher than that of ferrite widely used before, and it is better than the first generation and second-generation rare-earth magnets (SmCo permanent magnets). Nearly 1 time higher. It replaces "cobalt" with "iron" as raw material, which reduces the dependence on scarce strategic materials, and the cost is greatly reduced, making it possible for the wide application of rare earth permanent magnets. NdFeB is an ideal material for manufacturing high-efficiency, miniaturized, and light-weight magnetic functional devices, which will have a revolutionary impact on many application fields.

Due to China's advantages in rare earth raw material resources, my country has become the world's largest supplier of NdFeB magnetic materials, accounting for about 85% of the world's output. We have introduced the application fields of NdFeB products before. For example, new energy vehicles, aerospace, maglev trains, wind power generation, inverter air conditioners, etc. Today we will introduce those areas that are easily overlooked by us.

1. Traditional cars

The application of high-performance NdFeB in traditional automobiles is mainly concentrated in the field of EPS and micro motors. EPS electronic power steering can realize the power-assisted effect that the motor does not use at different speeds, ensuring that the car is light and flexible when steering at low speeds, and stable and reliable when steering at high speeds. EPS has high requirements on the performance, weight and volume of permanent magnet motors, because the permanent magnet materials in EPS are mainly high-performance NdFeB magnets, mainly sintered NdFeB magnets.

In addition to the starter that starts the engine on the car, the rest of the electric motors distributed in various places on the car are all micro motors. NdFeB permanent magnet material has excellent performance. It has the advantages of small size, light weight, high efficiency and energy saving when used in the manufacture of motors. In the past, automotive micro-motors were only used as wipers, windshield washers, electric oil pumps, automatic antennas and other components. The number of power sources is relatively small. Today's cars pursue comfort and automatic maneuverability, and micro motors have become an indispensable part of modern cars. Sunroof motors, seat adjustment motors, seat belt motors, electric antenna motors, baffle cleaning motors, cooling fan motors, air conditioner motors, electric water pumps, etc. all need micro motors. According to the estimation of the automobile industry, each luxury car needs to be equipped with 100 micro-motors, luxury cars need at least 60 units, and economical cars need to be equipped with at least 20 units.

2. Other transportation fields (high-speed rail, subway, tram)

In 2015, my country's "permanent magnet high-speed rail" was successfully tested. After adopting the rare earth permanent magnet synchronous traction system, due to the direct excitation drive of the permanent magnet motor, it has high energy conversion efficiency, stable speed, low noise, small size, light weight and reliability. And many other features, so that the original train with 8 carriages is equipped with power from 6 carriages to 4 carriages, which saves the cost of the traction system for 2 carriages, improves the traction efficiency of the train, and saves electricity by at least 10%. The whole life cycle cost of the train is reduced.

After the subway adopts NdFeB rare earth permanent magnet traction motor, the system noise is obviously lower than that of asynchronous motor at low-speed operation. The permanent magnet generator uses a new closed-ventilated motor design structure, which can effectively ensure that the internal cooling system of the motor is clean, eliminating the problem of filter clogging and cleaning caused by the exposed coils of the asynchronous traction motor in the past, making it safer and more reliable to use and less maintenance.

3. Consumer Electronics

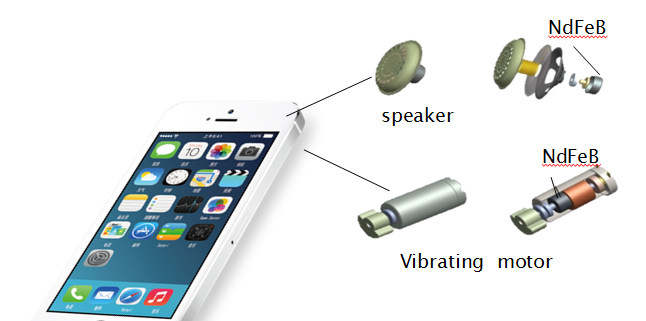

Mobile phone

High-performance NdFeB is an indispensable high-end accessory component in smartphones. The electro-acoustic parts of smartphones (miniature microphones, miniature speakers, Bluetooth headsets, high-fidelity stereo headsets), vibration motors, camera focusing and even sensor applications, wireless charging and other functions all require the application of strong magnetic properties of NdFeB.

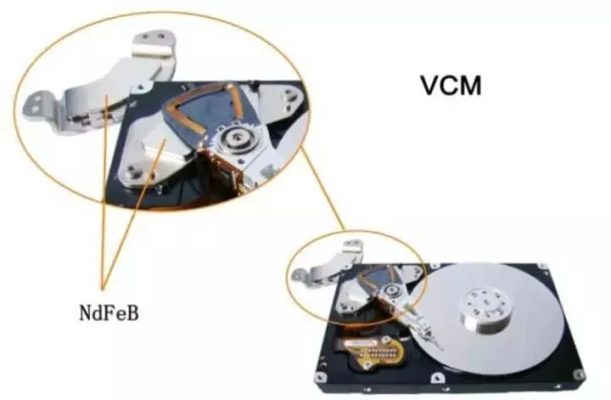

VCM

A voice coil motor (VCM) is a special form of direct drive motor that converts electrical energy directly into mechanical energy for linear motion. The principle is to put a barrel-shaped winding in a uniform air-gap magnetic field. The winding generates electromagnetic force to drive the load to reciprocate in a straight line. Changing the strength and polarity of the current can change the magnitude and direction of the electromagnetic force. VCM has the advantages of high response, high speed, high acceleration, simple structure, small size, good force characteristics, and control. In hard disk drives (HDD), VCM is mostly used as a disk head to provide movement, and it is an important core component of HDD.

4. Artificial Intelligence

Artificial intelligence and intelligent manufacturing have attracted more and more attention from people. Intelligent robots have become a core technology for human beings to reform the world, and drive motors are the core components of robots. Inside the drive system, miniature NdFeB is everywhere. According to the data, permanent magnet servo motors and NdFeB permanent magnet motors are the mainstream of robot motors at present. Servo motors, controllers, sensors and reducers are the core components of robot control systems and automation products. The joint movement of the robot is realized by the drive motor, which requires a very large power-to-mass and torque-to-inertia ratio, high starting torque, low inertia, and a smooth and wide speed regulation range. In particular, the actuator (handle) at the end of the robot should use a small and light motor as much as possible; when fast response is required, the driving motor must also have a large short-term overload capacity; high reliability and stability are the prerequisites for the application of driving motors in industrial robots are summarized, so rare earth permanent magnet motors are the most suitable.

v Artificial intelligence intelligent robot

v Manipulator, mechanical automatic production line

v Petroleum pumping unit

The permanent magnet motor has the characteristics of high efficiency and high fixed power, which can solve the problem of "big horse-drawn carts" in oil fields and achieve energy-saving effects.

v 3D printing