Multi-pole magnetic ring refers to a magnet filled with multiple magnetic poles. It is a ring magnet that is widely used in the field of motors. Through technological innovation, the stability and assembly problems at the end of use have been solved. Become the first choice for servo motors such as power tools, EPS power steering motors, etc. Compared with the current traditional technology, the cost is reduced by more than 30%, and the market is widely used!

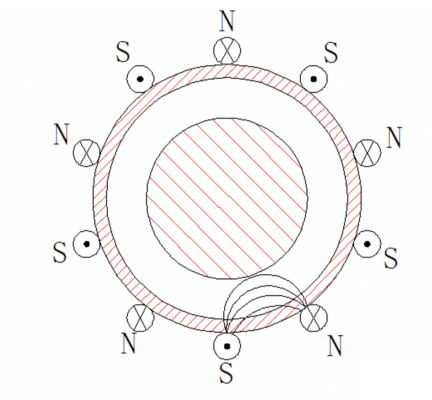

The multi-pole magnetic ring is to use a special magnetizer to magnetize the magnetic ring with the required number of pole pairs on the hard magnetic ring material. The magnetization effect is related to the material of the magnetic ring and the performance of the magnetizer. The size of the magnetic energy product and the hysteresis attenuation are related to the above situation. Of course, the structure and fixing method of the magnetic pole segment formed by the final magnetization will directly affect the efficacy of the multi-pole magnetic ring, because the direction of the magnetic pole segment directly affects the entire multi-pole magnetic ring. The energy of the magnetic field determines the quality of the magnetic performance, and if there is a hidden danger in the fixing method of the magnetic pole segments in the entire multi-pole magnetic ring, it will directly lead to whether the multi-pole magnetic ring becomes a scrap product standard.

According to different materials, multi-pole magnetic rings can be divided into NdFeB multi-pole magnetic rings, ferrite multi-pole magnetic rings, rubber magnetic multi-pole magnetic rings, and samarium-cobalt multi-pole magnetic rings. The first three are more common.

Among the above several multi-pole magnetic ring materials, the strongest magnetic force is the multi-stage magnetic ring of NdFeB magnet material. NdFeB magnets are known as "magnet kings" among the magnets and have high remanence. Among the multi-pole magnetic rings, those with the same specifications and magnetic poles have the strongest magnetic force. It is mainly used in the fields of high-performance permanent magnet motors and sensors.

In addition, according to different processes, NdFeB multipole magnetic rings are divided into sintered NdFeB multipolar magnetic rings and bonded NdFeB multipolar magnetic rings.

Ferrite magnet multi-pole magnetic ring is a product that is easy to produce. Ordinary axial multi-pole ferrite magnetic ring can produce multi-pole magnetic ring as long as there is a corresponding multi-pole magnetizing fixture. These are conventional magnets. Product common sense, but in the actual production process, the product quality of ferrite multi-pole magnetic rings is often affected by some uncertain external factors.

Ferrite magnetic rings mainly include nickel-zinc ferrite magnetic rings and manganese-zinc ferrite magnetic rings. Ferrite multi-pole magnetic rings have high magnetic properties, high surface magnetism, full radial magnetization, and can charge multiple poles. Ferrite multi-pole magnetic ring is an anti-interference component commonly used in electronic circuits, and it has a good suppression effect on high-frequency noise.

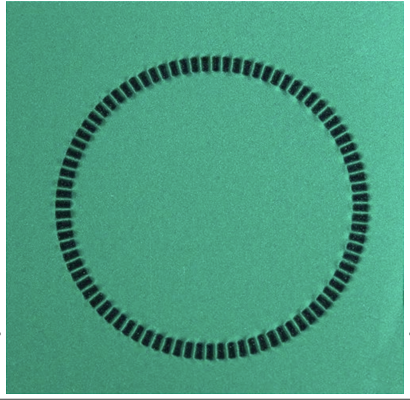

The cost of rubber magnetic multi-pole rings and ferrite multi-pole rings is relatively low, but the magnetic force will be relatively weak. At present, the most widely used products are circular magnetic grids, water pump motors, sweepers, etc.

The multi-pole magnetic ring made of samarium-cobalt material is the multi-pole magnetic ring with the highest temperature resistance. The maximum temperature of this material can reach 350 degrees, and it is currently the best magnet used in high-temperature environments.

As for the number of poles of the multi-pole magnetic ring, it also varies according to different customers, and the maximum can be hundreds of magnetic poles.

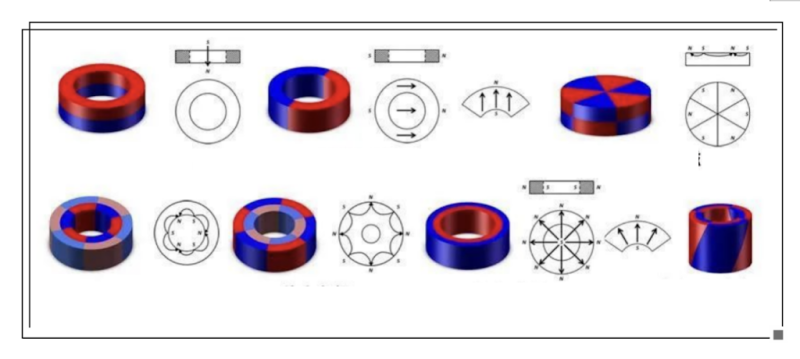

Multi-pole magnetic ring is a kind of magnet that is often used in motors, sensors, robots, and automation equipment. It is different from ordinary magnetization. There are multiple magnetic poles on one surface. In addition to the difference in materials, they also have magnetization methods.

Generally speaking, the material determines the magnetic field strength (magnetic performance) of the multi-pole magnetic ring, and the magnetization method determines its application. Common multi-pole magnetic rings are divided into the following types of magnetizations;

1.Axial multi-pole magnetization

2.Radial multi-pole magnetization

3.Outer diameter multi-pole magnetization (radial outer charging)

4.Inner diameter multi-pole magnetization (radial inner charging)

5.Plane multi-pole magnetization

6.Single-sided multi-pole magnetization

7.Full radial magnetization (radiation magnetization)

8.Oblique angle multi-pole magnetization

Generally speaking, multi-pole magnetization of magnetic rings requires the production of molds and magnetizing fixtures. Different materials require different costs for molds and magnetizing fixtures.