6 min read

Summary: The magnetic force drive transmission component is a non-contact magnetic force transmission type, which ensures transmit torque free-oil and quiet operation. Magnetic transmission products are classified into two types: A) Torque is transmitted from within the magnetic components, such as co-axial magnetic couplings and magnetic gearboxes. B) Torque is transmitted from outside the magnetic components, and the torque transmission is completed in a non-enclosed space. They require shaft-to-shaft fixation to transmit torque, such as magnetic gear transmissions for conveyors.

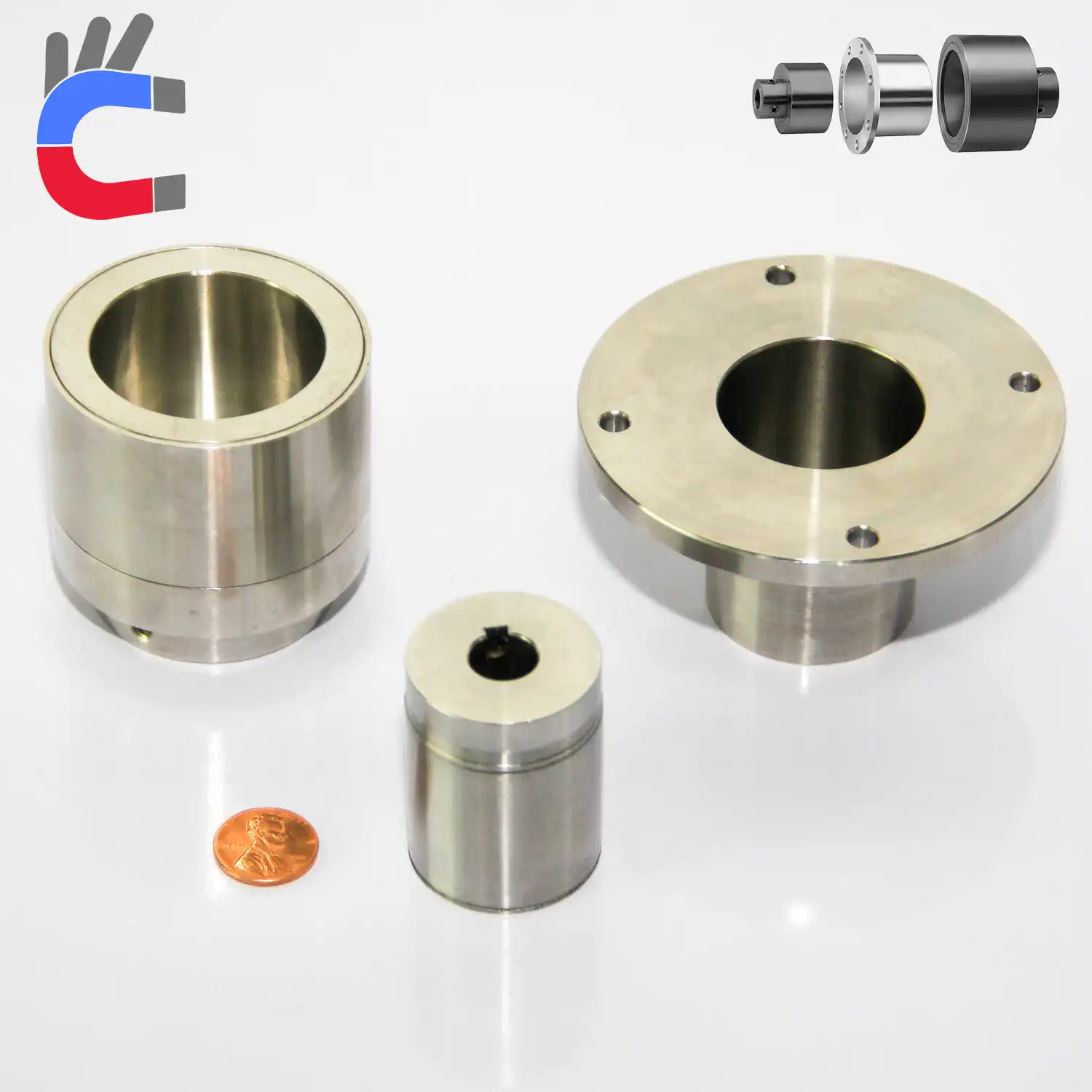

Application 1:Co-axial magnetic couplings( torque is transmitted internally )

In a co-axial magnetic coupling, torque is transmitted from within the magnetic components. Magnetic couplings transfer torque without contact, utilizing magnetic forces between the internal and external rotors. These couplings offer a hermetic seal between the driving and driven sides in pumps and agitators, reliably containing hazardous liquids and gases. As a result, they prevent serious leaks, serving as a dependable alternative to traditional dynamic shaft seals.

Operation / design

The coupling comprises an external and an internal rotor. The external rotor features high-quality, permanent magnets with varying polarities on its inner side, while the internal rotor has these magnets on its outer side.

Typically, the external rotor is mounted on the drive side and the magnets are secured in keyways using adhesive. In contrast, the magnets on the internal rotor, which is on the driven side, are fully encapsulated.

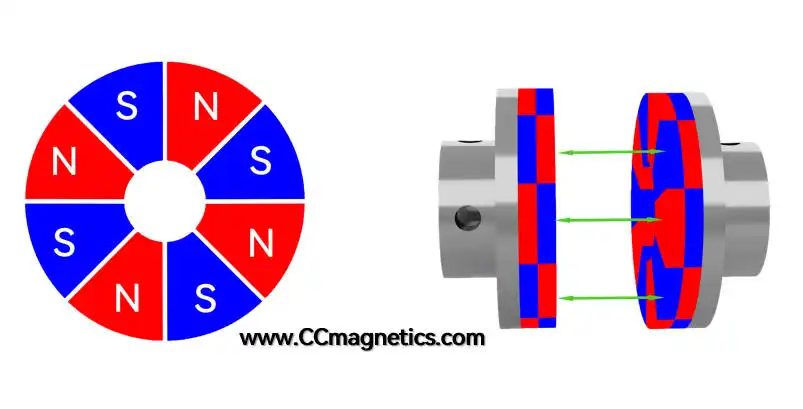

Torque transmission

In their non-operative state, the north and south poles of the rotors face each other, resulting in a completely symmetric magnetic field. Torque transmission occurs only when the rotors are twisted, causing the magnetic field lines to shift and thus transferring torque through the air gap. Under a constant torsion angle, synchronous operation is achieved. If the maximum coupling torque or the maximum torsion angle is exceeded, power transmission is interrupted.

Sealing function

The containment shroud, fixed to the housing, separates the internal and external rotors from each other, ensuring a completely leak-proof separation of the product from the atmosphere. The sealing is achieved statically, for example, with a flat seal or an O-ring, thereby eliminating the need for dynamically loaded sealing elements.

Application 2 :Magnetic disc couplings(Torque is transmitted externally)

Unlike co-axial magnetic couplings, magnetic disc couplings transmit torque from outside the magnetic components, exerting a magnetic pull on the shafts and frames that hold them in place. Consequently, magnetic disc couplings necessitate a robust frame to prevent the pulling force from deforming the fixed bracket. Such deformation would result in a smaller gap and alter the torque.

The advantage of magnetic disc couplings over co-axial magnetic couplings is their ability to accommodate a certain angle of connection tilt, which is compatible with the angle variation between two drive shafts. CCmagnetics offer customization of magnetic disc couplings to meet specific requirements. The torque range we support is from 0.05 to 18.5 N·m.

Application 3:Magnetic bevel gears ( Disc x Cylinder Type )

One half of the magnetic bevel gears consists of a large disc coupling, while the other half comprises a small magnetic gear. The transmission ratio is typically 1:1, although it can be customized to 2:1 or 3:1. We generally recommend that the motor end rotates more turns to minimize torque loss during the magnetic transmission process. Below are our demo images.

Application 4:Magnetic miter gears ( Cylinder x Cylinder Type)

Right-angled magnetic gears feature magnetic gears arranged at a 90° angle and are composed of two magnetic gears of the same size. When transmitting power through magnetic gears, it is important to note that the magnetic poles of magnetic helical gears are inclined. Therefore, if you require a magnetic transmission drive, make sure to confirm with the supplier that you need a 90° angle transmission. Magnetic constant diameter bevel gears differ from standard magnetic bevel gears; constant diameter bevel gears have restricted transmission ratios and limited torque due to the smaller contact surface area between the two gears. As an original manufacturer of magnetic transmission drives, we offer custom magnetic gears of any size or ratio.

Application 5:Parallel-axis magnetic gears ( Parallel axial cylinder type )

Parallel-axis magnetic gears, also known as parallel axial cylinder type magnetic gears, are driven in parallel, and they can have a large or small transmission ratio. Although their gear size appears similar to that of magnetic miter gears, their design with parallel magnetic poles results in a larger contact area between the N and S poles on the magnetic gear, allowing for the transmission of greater torque.

Regarding parallel-axis magnetic gears, we can tailor two gears of different sizes to fulfill your specific transmission ratio needs. This means that whether you require option magnetic spur gear or magnetic helical gear, we can customize them both accordingly.

Application 6:Magnetic rack & pinion gears ( Linear motion mechanism )

In the realm of mechanical gears, the definition of a rack and pinion gear system is as follows (refer to the left picture below), yet we design and produce magnetic versions using NdFeB magnets (illustrated in the right picture below). Concerning magnetic transmission drives, you can refer to the video provided for an example. These magnetic gears have small magnetic gears on one side and custom tracks crafted from neodymium iron boron magnets on the other, enabling them to offer lifting/lowering functionality or displacement torque.

CCmagnetics specializes in magnetic transmission drive components, which are among our most important product lines. As the original factory, we offer flexible customization and cost-effective solutions. For material options, we offer PVC, SUS304, SUS316, and other materials to meet various magnetic application needs. If you're interested, please contact us.