Polyvinyl chloride (PVC) is the world's third-most produced synthetic plastic polymer (after polyethylene and polypropylene). PVC was once the world's largest-volume plastic and has a wide range of applications. PVC exists in both rigid (sometimes abbreviated as RPVC) and flexible forms.

Rigid PVC is used in construction for pipes and windows. It is also used to manufacture plastic bottles, packaging, bank cards, and membership cards.

The addition of plasticizers can make PVC softer and more flexible. It can be used in pipes, cable insulation, flooring, signage, phonograph records, inflatable products, and as a rubber substitute.

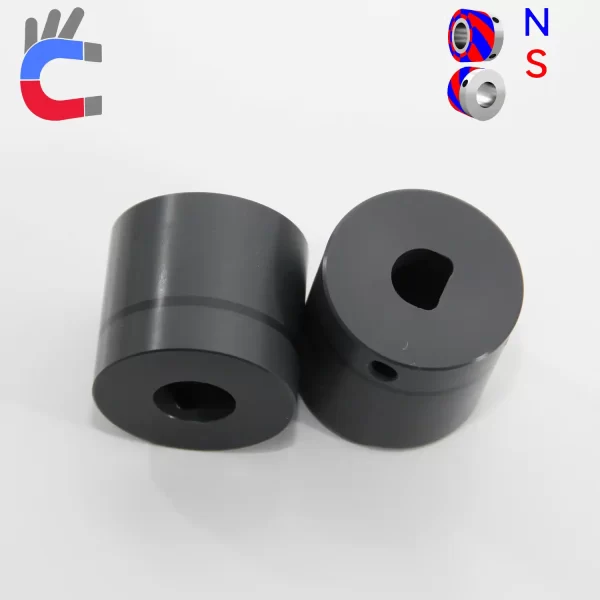

The Magnetic Transmission Components produced by CCmagnetics is made of rigid PVC.

Magnetic Gears

Pros of PVC Magnetic Transmission Components

- They have excellent resistance to acids, alkalis, and corrosion, making them suitable for chemical industrial applications.

- PVC couplings have a high resistance to water pressure, external pressure, and impact.

- PVC couplings have excellent electrical insulation properties, allowing them to be used simultaneously with electrical equipment.

- PVC material has been tested and proven not to affect water quality.

Magnetic Disc Couplings

Cons of PVC Magnetic Transmission Components

- Difficult to recycle: Although PVC boards are durable, they are difficult to recycle and may have a negative impact on the environment.

- Deforms easily at high temperatures: PVC boards can easily deform at high temperatures, so the operating temperature is -20 to 80 degrees Celsius.