Magnetic Drive Coupling,Magnet Linear Couplings,Magnetic Synchronous Coupling,Magnetic Motor Couplings,Magnetic Coupling System,Coaxial Torque Magnetic Coupling

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

What is magnetic drive coupling ?

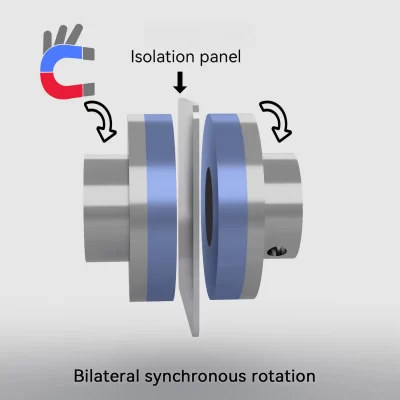

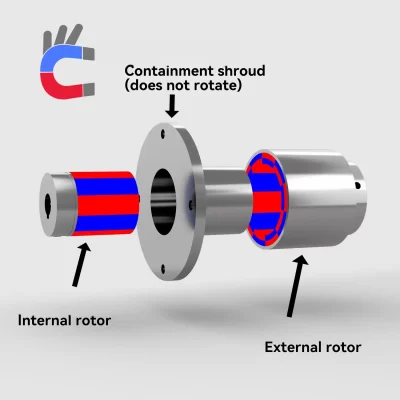

The magnetic drive coupling transmit the torque without contact through magnetic forces between the internal and external rotor. They ensure hermetic separation between driving and driven side in pumps and agitators sealing hazardous liquids and gases reliably.

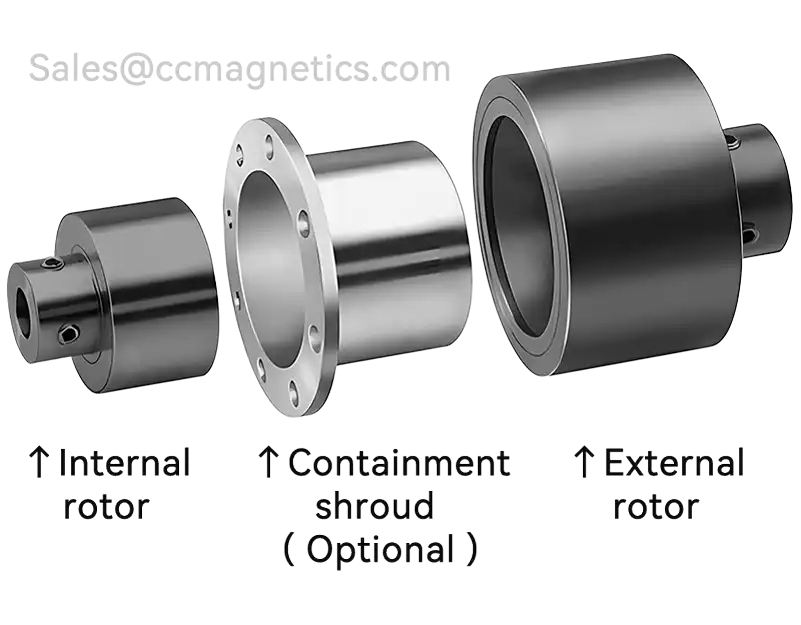

The magnetic drive coupling consists of an external and an internal rotor. The external rotor has got high-quality, permanent magnets of changing polarity on the inner side while the internal rotor has got them on the outside.The external rotor is usually fixed on the drive side and the magnets are glued in the keyways. The magnets of the internal rotor on the driven side are fully encapsulated.

How magnetic drive coupling work?

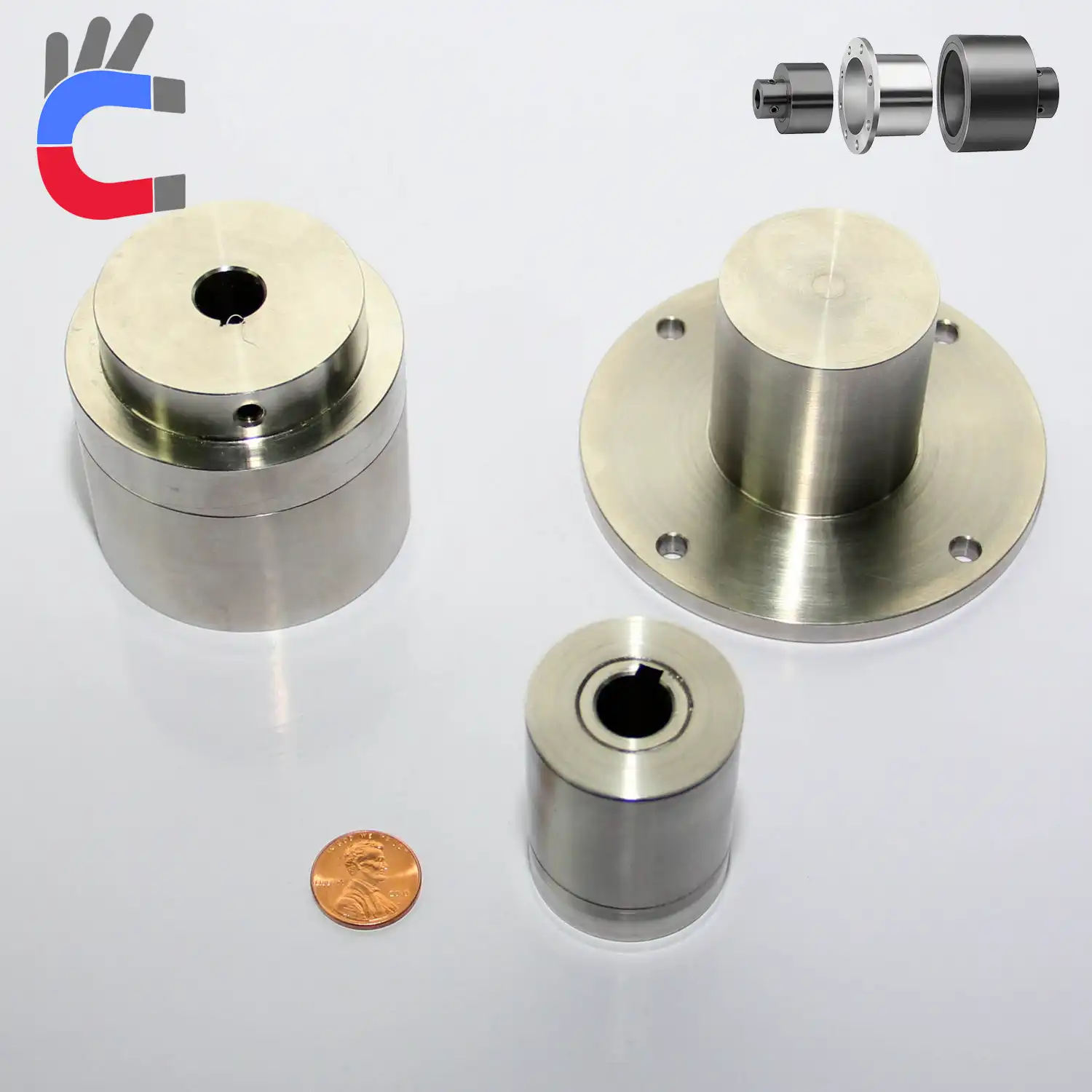

The magnetic drive coupling consists of three parts. The external rotor consists of a series of rare earth magnets that are ground, potted and attached to the inside diameter of a steel hub. The Internal rotor consists of a series of rare earth magnets that are ground, potted and attached to the outside diameter of a steel rotor. The sealing is achieved statically.

Then there is a synchronous operation under a constant torsion angle. If the maximum coupling torque and the maximum torsion angle are exceeded, the power transmission is interrupted.Since the torque transmission of the magnetic drive coupling is interrupted, the motor will be effectively protected.The motor will not burn out due to absolute torque transmission.

Application of magnetic drive coupling

Typical applications: Gear pumps, centrifugal pumps, screw spindle pumps, agitators, PU foaming lines.

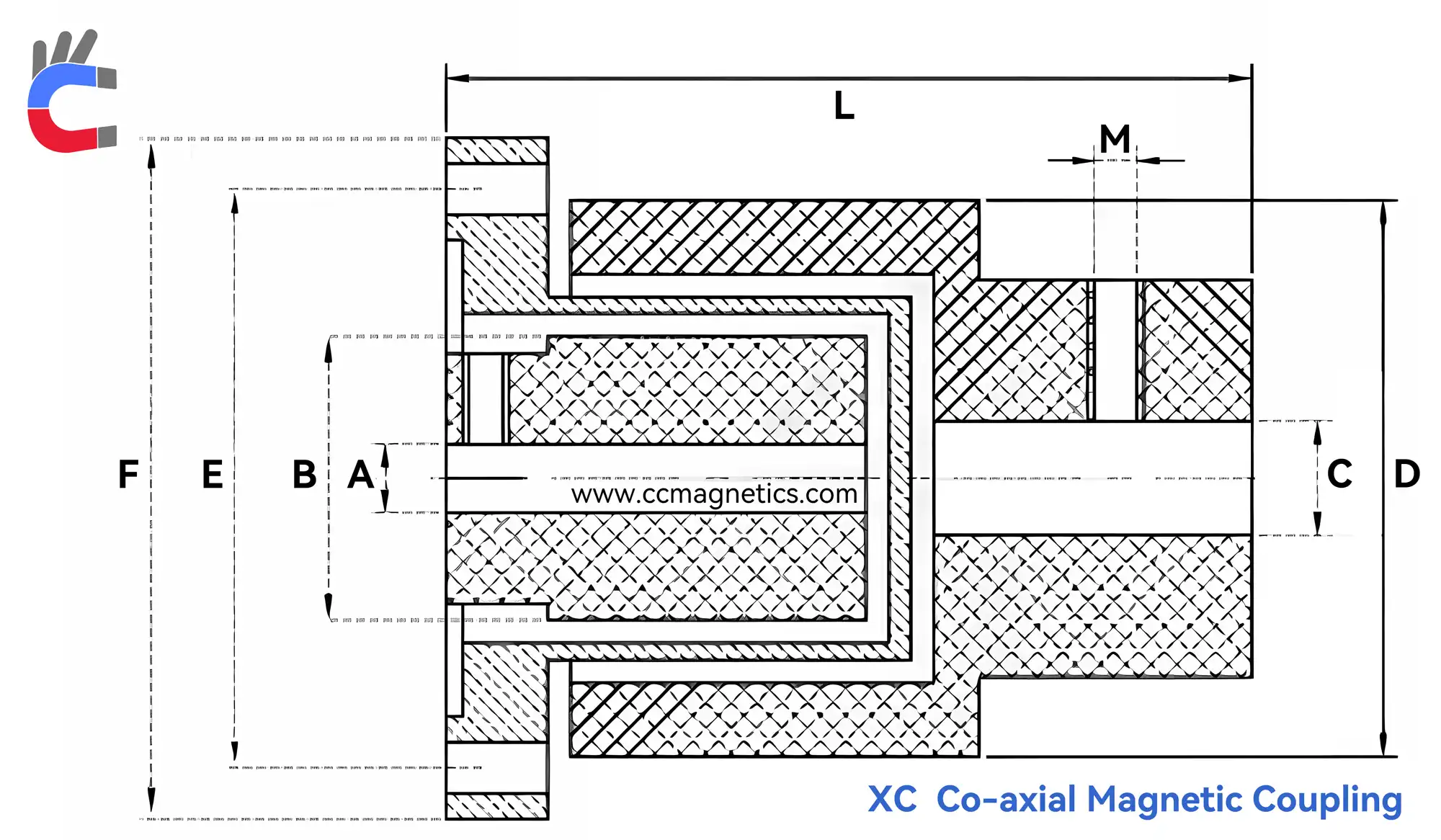

The magnetic drive coupling parameter

| Model | D | ΦC | M | B | ΦA | Nominal Torque [N.m] |

L | F | E |

|---|---|---|---|---|---|---|---|---|---|

| XC45 | 45 | 8~19 | M4 | 27 | 6~15 | 2N.m | 67 | 65 | 55 |

| XC60 | 60 | 12~24 | M5 | 35 | 8~18 | 5.4N.m | 78 | 90 | 77 |

| XC62 | 62 | 12~24 | M5 | - | 8~18 | 6N.m | 76 | - | - |

| XC80 | 80 | 15~28 | M6 | 48 | 10~20 | 11.5N.m | 90 | 115 | 99 |

| XC90 | 90 | 15~28 | M8 | - | 10~20 | 15N.m | 137 | - | - |

| XC90L | 90 | 15~28 | M8 | - | 10~20 | 25N.m | 151 | - | - |

| XC100 | 100 | 25~35 | M8 | 58 | 15~25 | 43.8N.m | 129 | 142 | 122 |

| XC120 | 120 | 28~35 | M8 | 70 | 15~30 | 84N.m | 137 | 165 | 145 |

| XC164 | 164 | 30~40 | M8 | - | 15~30 | 100N.m | 174 | - | - |

| Model | D | ΦC | M | B | ΦA | Nominal Torque [in-lb] |

L | F | E |

|---|---|---|---|---|---|---|---|---|---|

| XC45 | 1.77 | 0.31~0.75 | M4 | 1.06 | 0.24~0.59 | 18 | 2.64 | 2.56 | 2.17 |

| XC60 | 2.36 | 0.47~0.94 | M5 | 1.38 | 0.32~0.71 | 48 | 3.07 | 3.54 | 3.03 |

| XC62 | 2.44 | 0.47~0.94 | M5 | - | 0.32~0.71 | 53 | 2.99 | - | - |

| XC80 | 3.15 | 0.59~1.10 | M6 | 1.89 | 0.39~0.79 | 102 | 3.54 | 4.53 | 3.9 |

| XC90 | 3.54 | 0.59~1.10 | M8 | - | 0.39~0.79 | 133 | 5.39 | - | - |

| XC90L | 3.54 | 0.59~1.10 | M8 | - | 0.39~0.79 | 221 | 5.94 | - | - |

| XC100 | 3.94 | 0.98~1.38 | M8 | 2.28 | 0.59~0.98 | 388 | 5.08 | 5.59 | 4.8 |

| XC120 | 4.72 | 1.10~1.38 | M8 | 2.76 | 0.59~1.18 | 744 | 5.39 | 6.5 | 5.71 |

| XC164 | 6.46 | 1.18~1.57 | M8 | - | 0.59~1.18 | 885 | 6.85 | - | - |

Customizable Items:

- 1. Third-party authoritative testing available. Globally recognized torque and material test reports issued by authoritative organizations are provided.

- 2. Flexible options for surface metal materials. The metal material can be flexibly customized. Stainless steel 304 is used as the standard material, with stainless steel 316 available as an optional choice.

- 3. No MOQ and Global Door-to-Door Delivery. We offer global door-to-door delivery service with no minimum order quantity (MOQ).

- 4. Shaft Diameter and Shape (Free Service). You can choose the shaft's size and shape to meet your specific needs.

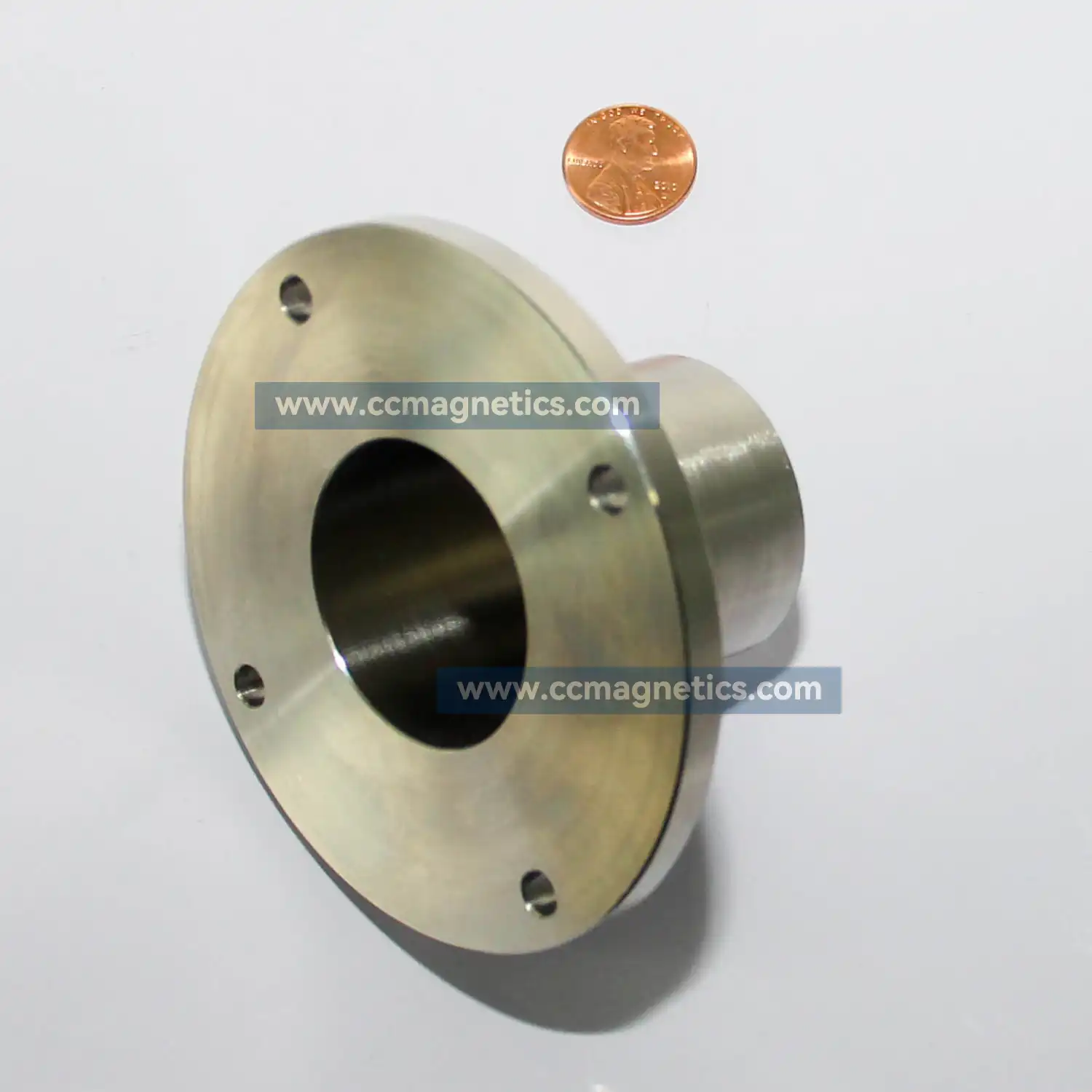

- 5. Containment shroud (optional).

- 6. Custom rubber sealing rings available.

- 7. Various magnet grades and material options. - Maximum temperature resistance: 300°C. - Torque adjustable based on magnet grade and type (optional neodymium magnets. and samarium cobalt magnets).

Shaft fixing method

Magnetic disc vs co-axial coupling comparison

| Magnetic disc vs co-Axial coupling comparison |

|

|

|---|---|---|

| Coupling style | Magnetic disc couplings ( XD ) | Co-axial magnetic couplings ( XC ) |

| Permanent-magnetic | √ | √ |

| Contactless | √ | √ |

| Maintenance-free | √ | √ |

| Torsionally flexible | √ | √ |

| Low vibrations | √ | √ |

| Material | Standard: SS304. Options: Aluminum alloy 6061,Stainless steel 316L,PVC, available) |

Standard: SS304. Options: SS316/UNS S31603. |

| Containment shroud | None | Optional |

| Axial forces | High axial force which must be restrained | Coupling finds its own center with ~0 axial force |

| Shaft fixing method | Small size type A, big size type B & C available |

Type B |

| Slip torque adjustment | Air gap can be adjusted to increase or decrease slip torque |

Coupling hubs can be seperated axially to decrease slip torque (axial force will result) |

| Angular misalignment capacity | 3° Max | Ensure coupling hubs (or barrier if used) do not contact |

| Parallel misalignment capacity | 6.35mm (0.25in) Max | Ensure coupling hubs (or barrier if used) do not contact |

| Containment barrier | Simple flat barrier | Top-hat shaped barrier |

| Max. pressure resistance [bar] | Up to 80 bars depending on size | Up to 90 bars depending on size |

| Max. temperature resistance [°C] | 150/300 depending on magnet material | 150/300 depending on magnet material |

Please Note:

- The magnetic drive coupling containment shroud is optional, we can produce it according to your drawings, the larger the order quantity, the better the discount.

- We are the original manufacturer for magnetic drive coupling, we provide very flexible customizability; any grade of magnet, any material, one-year warranty, lifetime technical support.

jdkshepard –

good!

billeysimp –

Great!

skylarthompson44 –

Great communication, prompt delivery