Non-Contact Magnetic Drives Models,Magnetic conveyor track,Magnetic pinion components,Rotary magnetic power transmission,Non-friction magnetic transmission gear

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

About magnetic rack & pinion gears

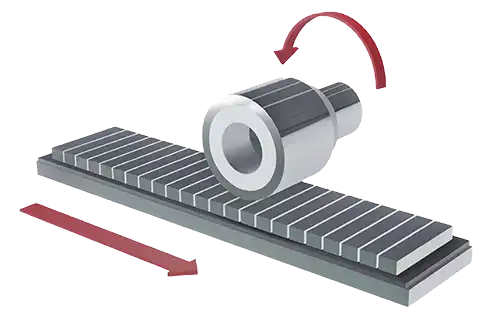

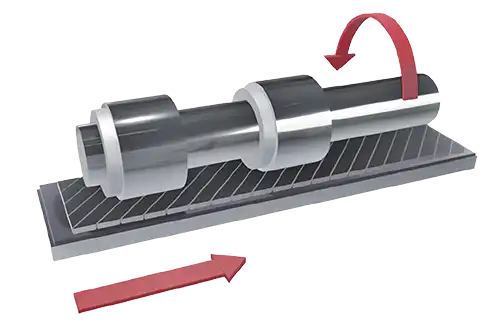

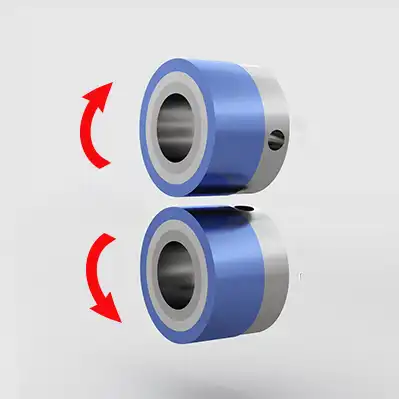

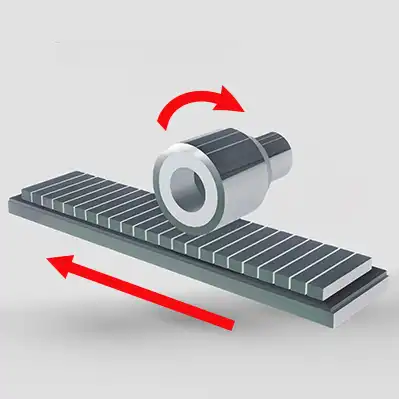

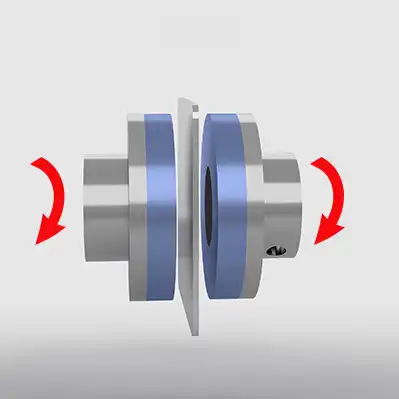

This proposal introduces an unprecedented new type of transportation rack that transforms into a rack simply by being attached. It incorporates a magnetic rack & pinion gear system, which operates on two transmission modes: Parallel and right-angle. Standardly, the system utilizes magnetic gears with an outer diameter of 35mm. However, magnetic gears with larger diameters can be employed as well, tailored to specific customer usage requirements.

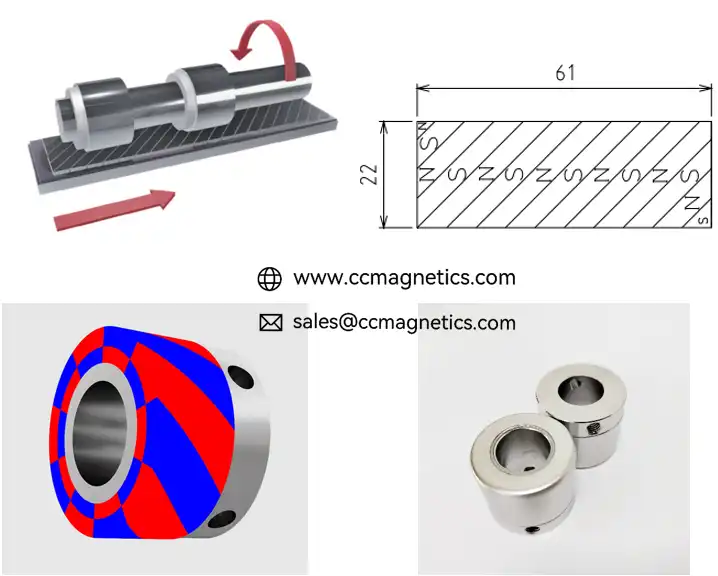

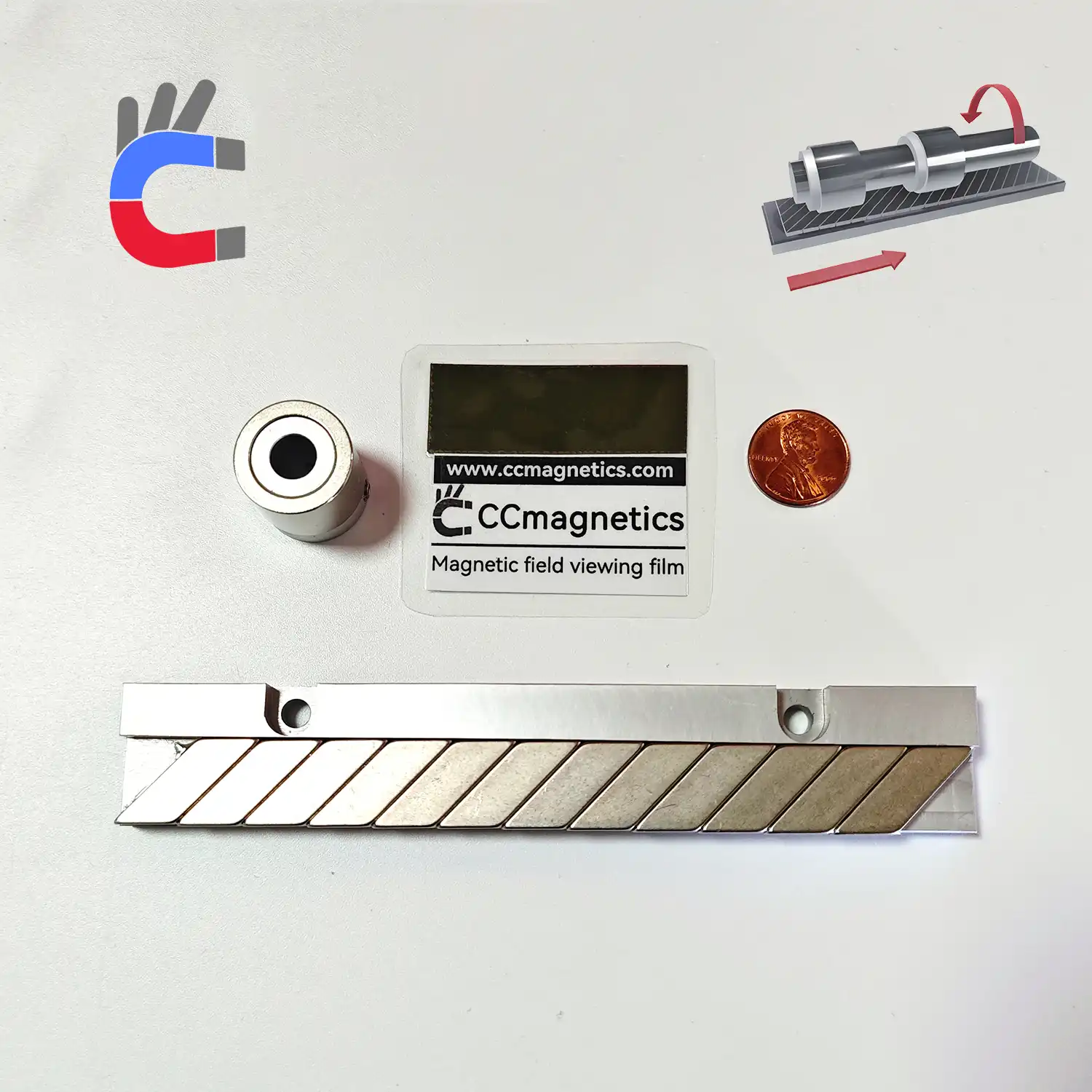

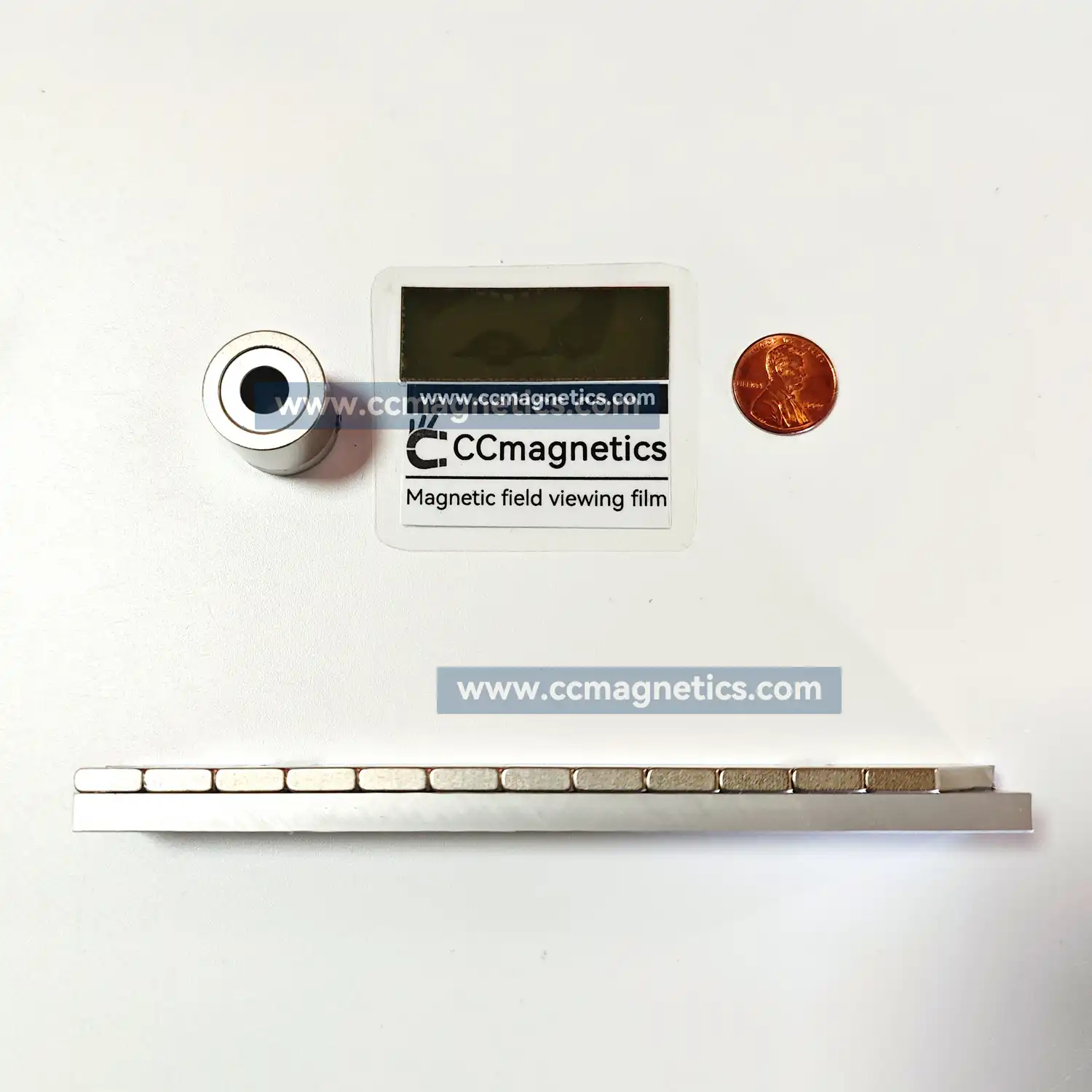

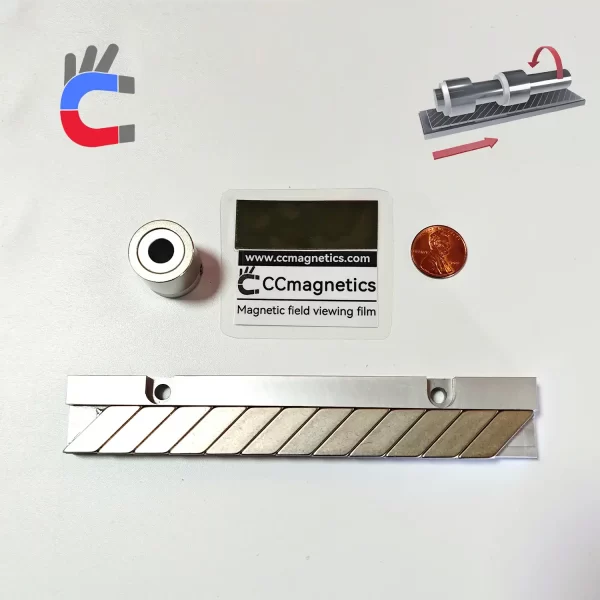

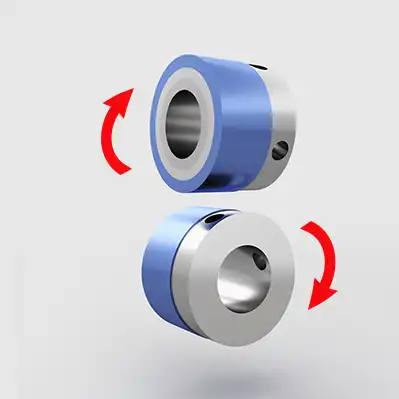

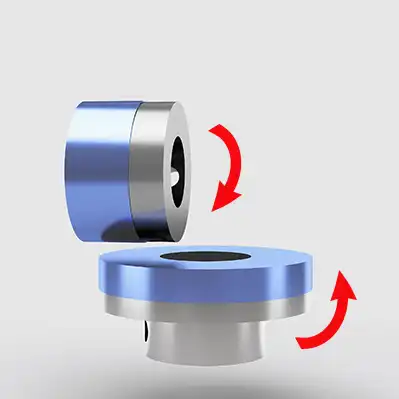

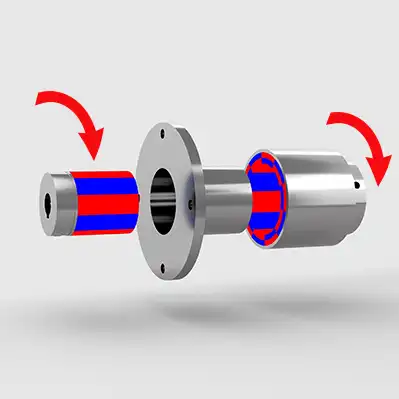

There are two types of magnetic rack & pinion gears, parallel type and cross type. Their transmission methods are different. You can refer to the following pictures:

Product Parameter

Cross Type: Pinion ( MGS-A ) outer diameters range from 13 mm to 65 mm, with custom shaft diameters. Magnetic track widths can be customized from 8 mm to 35 mm, and track lengths can be customized to any desired length.

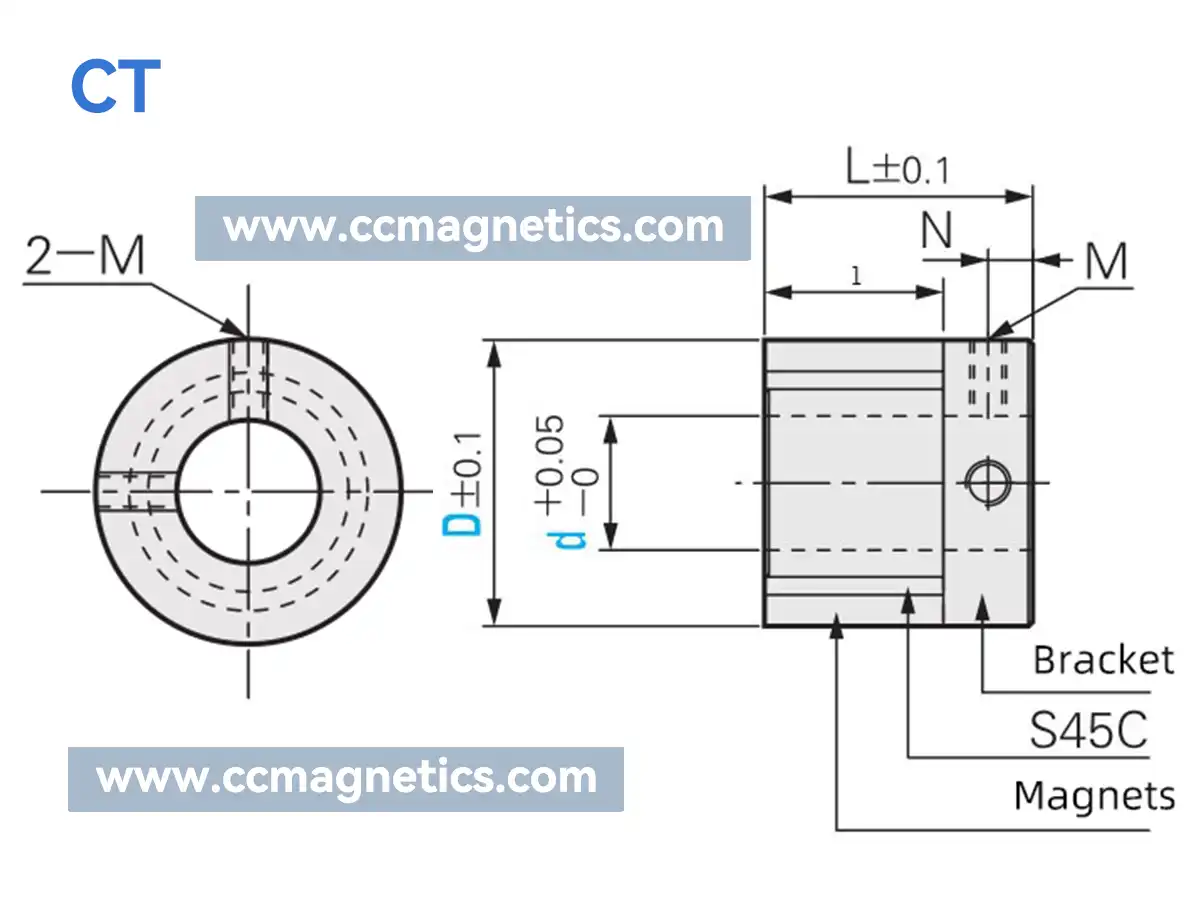

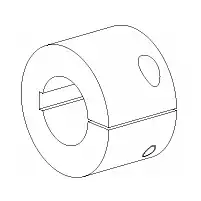

Pinion parameter

Please note:

Please note:

- BRA: Brackets, A=A6061,S=SUS304

- IRO: Iron ring,C=ENHANCED,X=NORMAL

- FIX: Fixed method: C or A , When O.D>=21mm, optional A or C, O.D <21mm, only A.

- Tor: Torque (Gap:1mm)

Shaft fixing method

| Part Number |

(D) O.D | Pole Qty | (d) I.D | Bra | Iro | Fix | Tor | L | l | N | M |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CT | 13 | 6P | 4,5,6 | A/S | C/X | C/A | 0.012N.m | 15 | 10 | 2.5 | M3 |

| CT | 16 | 8P | 5,6,8 | A/S | C/X | C/A | 0.025N.m | 13 | 8 | 2.5 | M3 |

| CT | 16 | 12P | 5,6,8 | A/S | C/X | C/A | 0.015N.m | 13 | 8 | 2.5 | M3 |

| CT | 18 | 8P | 6,8 | A/S | C/X | C/A | 0.05N.m | 15 | 10 | 2.5 | M3 |

| CT | 21 | 6P | 6,8,10,12 | A/S | C/X | C/A | 0.13N.m | 21 | 15 | 3 | M4 |

| CT | 21 | 8P | 6,8,10,12 | A/S | C/X | C/A | 0.11N.m | 21 | 15 | 3 | M4 |

| CT | 21 | 16P | 6,8,10,12 | A/S | C/X | C/A | 0.07N.m | 21 | 15 | 3 | M4 |

| CT | 22 | 18P | 6,8,10,12 | A/S | C/X | C/A | 0.07N.m | 18 | 12 | 3 | M4 |

| CT | 25 | 10P | 6,8,10,12,15 | A/S | C/X | C/A | 0.15N.m | 22 | 15 | 3.5 | M4 |

| CT | 26 | 8P | 6,8,10,12,15 | A/S | C/X | C/A | 0.2N.m | 21 | 14 | 3.5 | M4 |

| CT | 26 | 10P | 6,8,10,12,15 | A/S | C/X | C/A | 0.16N.m | 21 | 14 | 3.5 | M4 |

| CT | 26 | 12P | 6,8,10,12,15 | A/S | C/X | C/A | 0.14N.m | 21 | 14 | 3.5 | M4 |

| CT | 26 | 20P | 6,8,10,12,15 | A/S | C/X | C/A | 0.05N.m | 21 | 14 | 3.5 | M4 |

| CT | 28 | 8P | 8,10,12,15 | A/S | C/X | C/A | 0.22N.m | 25 | 17 | 4 | M4 |

| CT | 29 | 8P | 8,10,12,15 | A/S | C/X | C/A | 0.25N.m | 25 | 17 | 4 | M4 |

| CT | 30 | 8P | 10,12,15 | A/S | C/X | C/A | 0.31N.m | 25 | 18 | 3.5 | M4 |

| CT | 30 | 10P | 10,12,15 | A/S | C/X | C/A | 0.28N.m | 25 | 18 | 3.5 | M4 |

| CT | 32 | 08P | 8,10,12,15,20 | A/S | C/X | C/A | 0.4N.m | 30 | 20 | 5 | M4 |

| CT | 32 | 10P | 8,10,12,15,20 | A/S | C/X | C/A | 0.32N.m | 30 | 20 | 5 | M4 |

| CT | 32 | 12P | 8,10,12,15,20 | A/S | C/X | C/A | 0.28N.m | 30 | 20 | 5 | M4 |

| CT | 32 | 20P | 8,10,12,15,20 | A/S | C/X | C/A | 0.09N.m | 30 | 20 | 5 | M4 |

| CT | 35 | 08P | 8,10,12,15,20 | A/S | C/X | C/A | 0.55N.m | 32 | 21.5 | 5.25 | M5 |

| CT | 35 | 10P | 8,10,12,15,20 | A/S | C/X | C/A | 0.45N.m | 32 | 21.5 | 5.25 | M5 |

| CT | 35 | 12P | 8,10,12,15,20 | A/S | C/X | C/A | 0.36N.m | 32 | 21.5 | 5.25 | M5 |

| CT | 35 | 18P | 8,10,12,15,20 | A/S | C/X | C/A | 0.36N.m | 32 | 21.5 | 5.25 | M5 |

| CT | 39 | 08P | 15,17,20 | A/S | C/X | C/A | 0.8N.m | 35.8 | 26.6 | 4.6 | M5 |

| CT | 39 | 12P | 15,17,20 | A/S | C/X | C/A | 0.58N.m | 35.8 | 26.6 | 4.6 | M5 |

| CT | 39 | 16P | 15,17,20 | A/S | C/X | C/A | 0.4N.m | 35.8 | 26.6 | 4.6 | M5 |

| CT | 40 | 16P | 15,20,25 | A/S | C/X | C/A | 0.42N.m | 34 | 24 | 5 | M5 |

| CT | 42 | 12P | 15,20,25 | A/S | C/X | C/A | 0.74N.m | 30 | 21 | 4.5 | M5 |

| CT | 42 | 18P | 15,20,25 | A/S | C/X | C/A | 0.42N.m | 30 | 21 | 4.5 | M5 |

| CT | 45 | 10P | 15,20,25,30 | A/S | C/X | C/A | 1.2N.m | 35 | 25 | 4.5 | M4 |

| CT | 45 | 12P | 15,20,25,30 | A/S | C/X | C/A | 0.95N.m | 35 | 25 | 4.5 | M4 |

| CT | 52 | 10P | 20,25,30,35 | A/S | C/X | C/A | 1.45N.m | 37 | 25 | 5 | M5 |

| CT | 65 | 18P | 20,35,40 | A/S | C/X | C/A | 1.95N.m | 50 | 35 | 7.5 | M5 |

Magnetic track parameter

| Magnetictrack width | Aswide as the magnet part of the pinion gear. |

|---|---|

| Magnetictrack lenth | Customizable |

| Material | Neodymiumsintered magnet / 6061 aluminium alloy |

| Surfacetreatment | Ni-Cu-Ni( Magnets ) |

| Max.operatingtemperature | 80°C |

Note:

- When there are few magnetic poles, the torque becomes larger. The disadvantage is that the transmission stability is poor and there is shaking during transmission;

- When there are many magnetic poles, the stability is good, but the transmission torque will become smaller. Mixing of medicines and chemicals is suitable for magnetic gear with multiple magnetic poles.

- It is easy to connect and remove racks, and you can change the length according to your imagination.

- Since it is non-contact, no lubricating oil or grease is required.

- The rack mount base can be provided by the customer or customized by us.

- Please contact us for the rack base material, surface treatment, and magnet installation method.

steve –

Mr Magnets were great however , courier company let you down by leaving our magnets outside an office which had nothing to do with us on the same level one , if he looked over to the right as he came up the stairs our office is well marked , luckily we went looking for the magnets after receiving an email to say magnets had been delivered,not good.